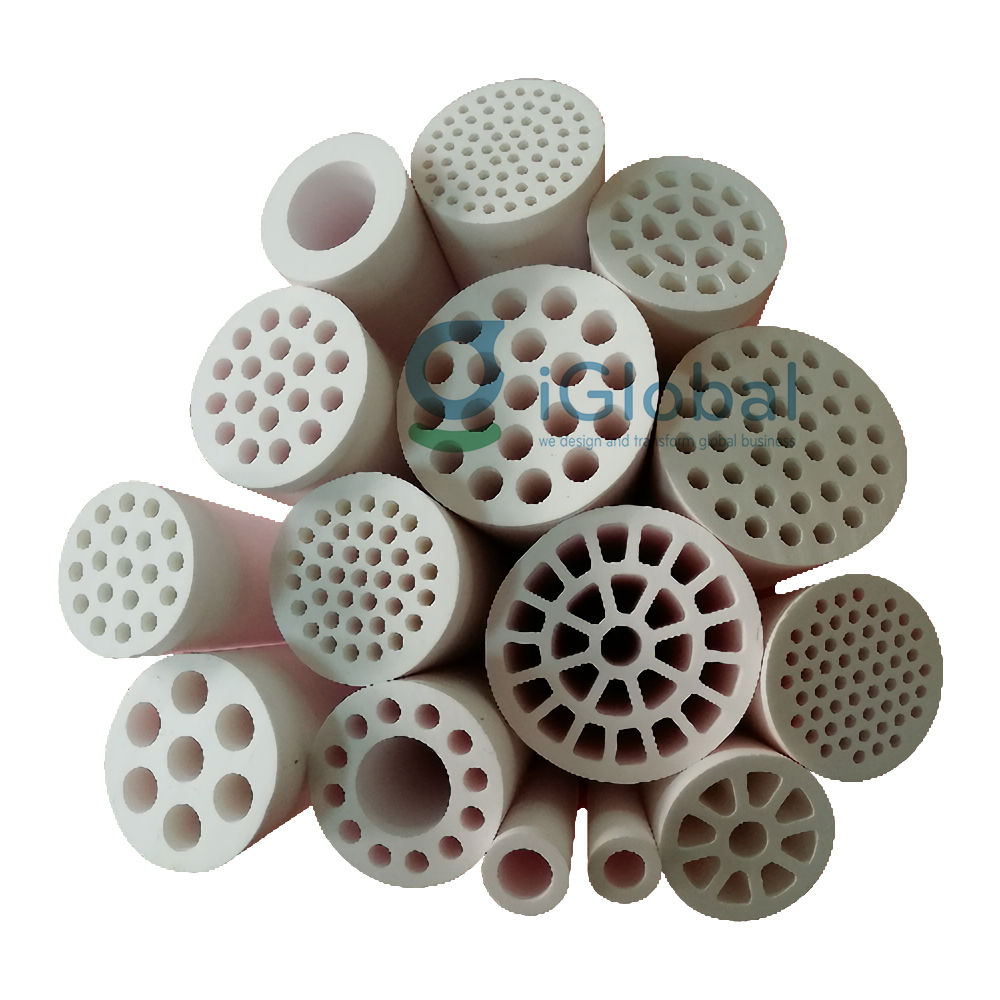

A filter nozzle has three main components: a filter with slots to retain filter media or gravel, a water control hole, and an exhaust manifold with small holes to control airflow (for long tail nozzle caps with wind groove).

What is a filter nozzle?

Filter nozzle caps can rely on the open area of the slits to provide loss and distributed water flow. The slots of the nozzle may be partially blocked by the filter material. This will change the resistance across the slots. If the water control hole is located in the body of the filter and the slots have a larger opening area, it will be less affected by the slots clogged by the nozzle.

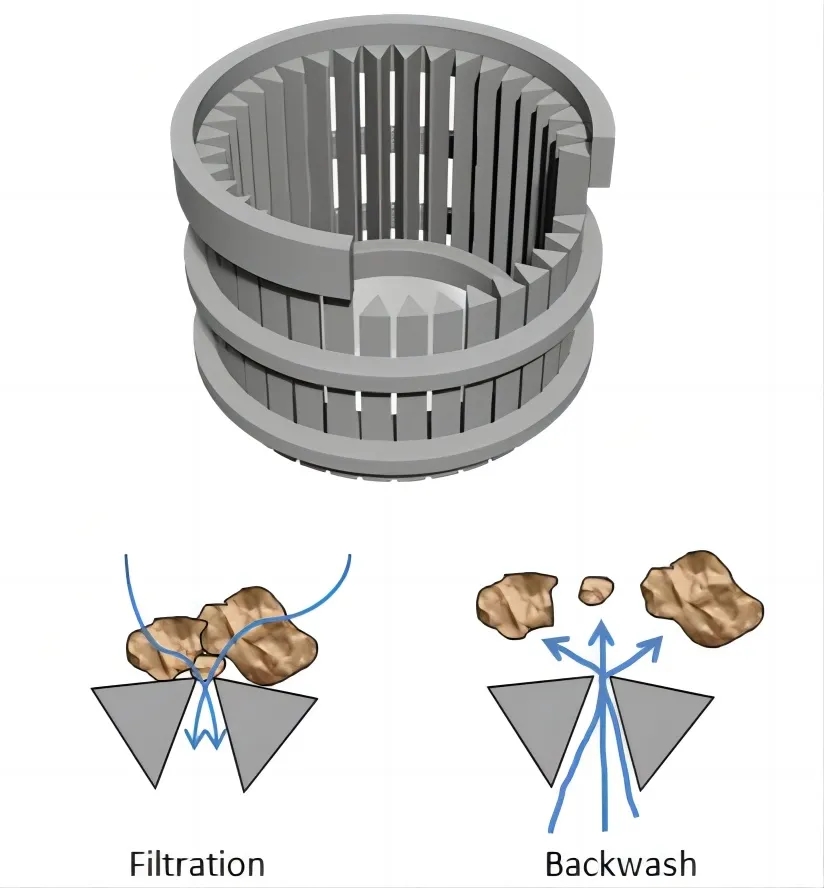

The slot size of the nozzle varies considerably from about 0.2mm to about 10mm, larger slots are best suited for flow filters. Slots 0.2, 0.3 & 0.35mm are often used for direct contact with the filter media without requiring a gravel support on the nozzle’s face. This direct contact has the advantage of combining aeration and backwashing with water.

The function of the exhaust manifold of the long-tail nozzle is to control the air distribution. If air is not used to wash the filter, it is not necessary to use this air duct. Exhaust pipes are usually provided with a small upper hole (start or air outlet) and lower holes or slots (metering hole/slot). When air is applied to the floor whether suspended or dispersed, the air will condense on the floor and push the water down until the air reaches the metering hole or slit under the tail of the nozzle. The measuring hole is properly sized to prevent air from reaching the end of the tube end. If the air reaches the end of the tube, this will cause poor air distribution and localized aeration causes uneven distribution, possibly too strong air bubbles pushing the material into the drainage channels and mixing. if using a multistage filter.

Filter nozzles can be made of a variety of materials such as plastic and metal and are supplied with ancillary components that can be fitted to concrete foundation, metal floors and side piping systems.

Working principle of filter nozzle

Filtration is an important part of the water treatment process. In the filter tank of the water supply plant, when the filter water is working, the porosity of the filter material is continuously reduced along with the increase of sediment on the filter material layer during the working cycle, the sludge will penetrate deeper into the material layer. The filter increases the resistance to the filtered water flow. As a result, the filtration speed is reduced, the water level on the surface of the filter is gradually increased (most visible in gravity filter tanks), and finally increases the turbidity of the filtered water.

In order to restore the normal operation of the filter in a short time and ensure the quality of the output water, it is necessary to carry out backwashing to push out all the dirt.

Practice has proven that the combined gas-water backwash method is better than the pure water backwash method. The combined air-water backwashing can destroy the structure of the sludge ball in the filter media. When the air is discharged, the filter material produces a large oscillation, the filter material collides many times, and has good friction with each other. The filter layer is strongly stirred, the sludge ball cannot form and if there is a sludge ball structure, it is also destroyed by the vibration and the adhesions on all the filter materials are separated and released by the backwash water.