What is a filter press? Let’s interpret it through the following itmes

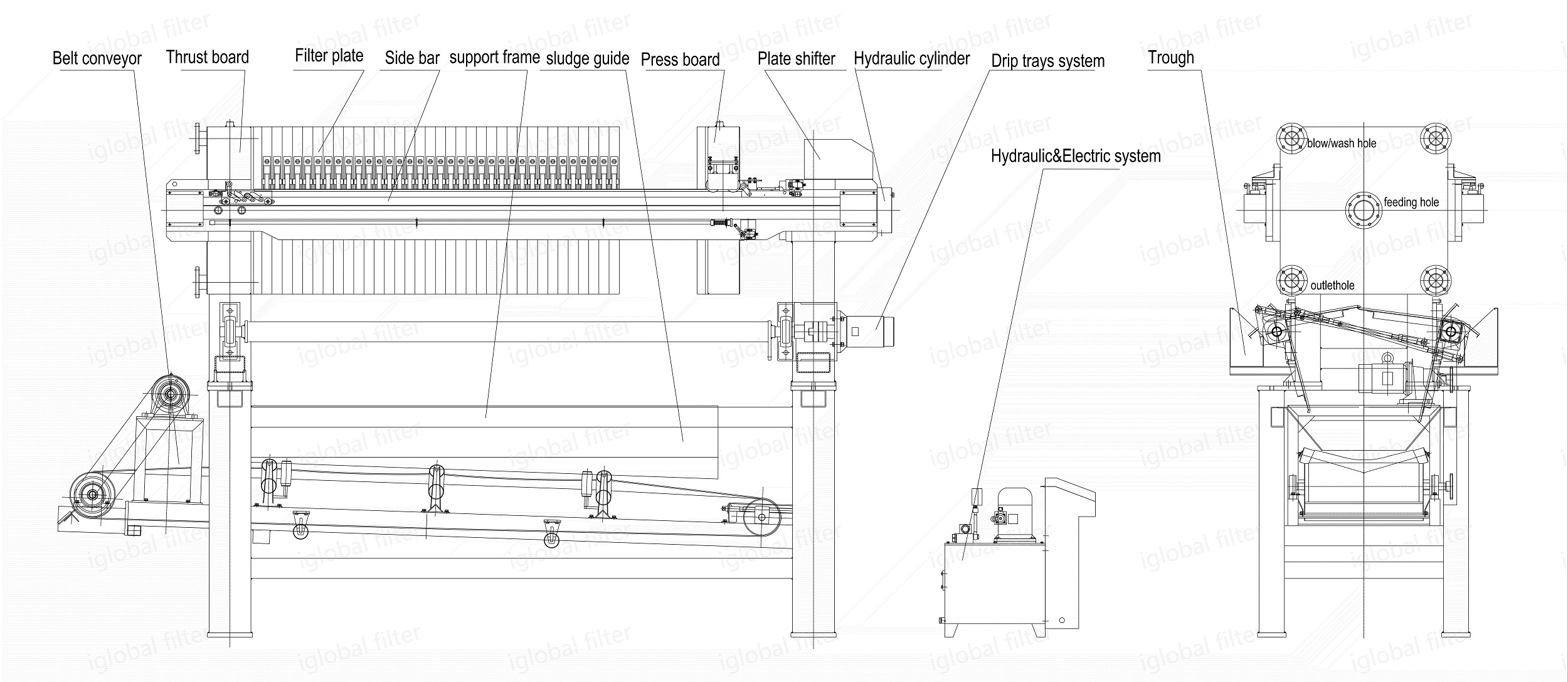

1. Construction describe

Filter press is advanced seperation machinery products integrated in its design with engine, electricity and liquid as a whole.This type of filter press consists of five Main Parts: machine frame part, filtering parts (filter plates, filter cloth), auto. Plate separate system part, conveyor belt part, hydraulic and electric system part. And also Sunshine filter press can equip more extra systems such as auto. Feeding system, auto. Saftey light guards system, auto. drip trays system, touch screen and PLC system etc.

1). Machine frame part

Machine frame is the base of the whole machine, used for supporting filter mechanism and connecting other parts. It is mainly composed of thrust board, pressing board, Hydraulic cylinder and side bars. When the machine is under working, the piston of the hydraulic cylinder will push on the pressing board to compact the filter plates, so as to make sure the feed slurry can be filtered in the chamber.

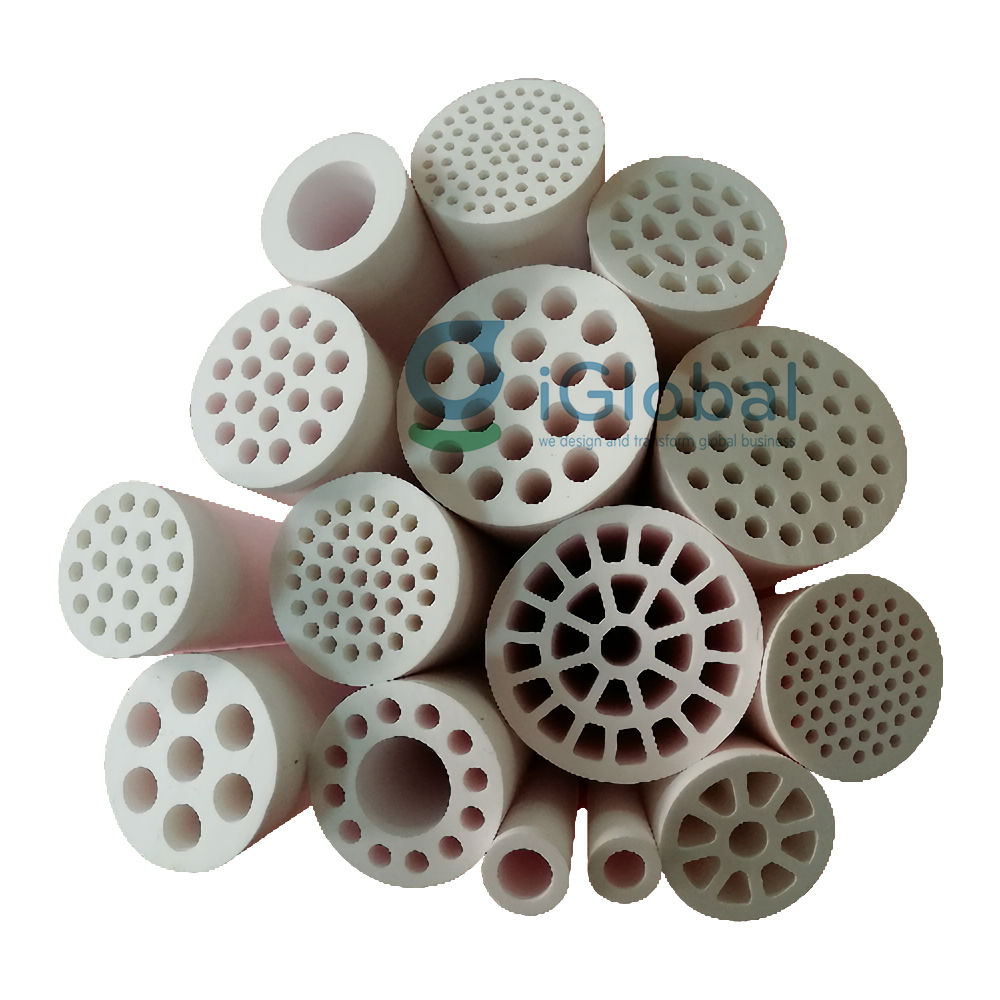

2). Filtering parts

Filtering parts consist of filter plate that are orderly-arranged on the side bars, filter cloth between the filter plates. The interlacing arrangement of filter plate and filter cloth form filtering unit-filter chamber, one after another (See figure 5: filtering and washing flow chart). At the beginning of filtering, slurry is feeding by pumps(usually can choose air diagram pump or screw pump) into each filter chamber through the feeding holes in the thrust board, there solid-liquid separation is carried out by the pressure produced by feed pump. The solid matters will remain in the filter chambers to form filter cake due to the filter cloth while filtrate will be discharged through water nozzles (open discharge type) or filtrate dishcarge pipe(close discharge type). If the filter cakes need to be washed, water can be enter into the washing holes on the thrust board to through the filter cakes. Similarly, if you want to get filter cakes with low moisture content, you can enter the compressed air through the washing holes too(applicable for Uk Model Machine, see figure4: pipe drawing).

The choice of filter cloth has decided influence on the filtering effect. During the using process of the filter press, filter cloth plays a key role, whether its features are good, whether its pattern selection is correct will directly influence the filtering effect. Nowadays, the most often seen filter cloth is made from synthetic fibre, which can be divided into terylene, fibrous fibre , polypropylene and polyamide fibre. See the Table below for the following features.

| Feature | terylene | polyamide fibre | polypropylene, | fibrous fibre |

| acid resistance | Strong | Relatively poor | Less good | Resistant no acid |

| alkaline resistance | Weak alkaline resistance | Less good | strong | Strong alkaline resistance |

| electrical conductivity | Very poor | Relatively good | Less good | common |

| breaking elongation | 30%-40% | 18%-45% | Larger than terylene | 12%-25% |

| Reversion ability | Very good | Reversion rate can be above 90% when the extension is within 10% | A litter better than that of terylene | Relatively poor |

| abrasion performance | Very good | Very good | Good | Relatively good |

| heat resistance | 170℃ | Shrink a little when above

130℃ |

Shrink a little when above 90℃ | Shrink a little when above

100℃ |

| softening point | 230-240℃ | 180℃ | 140-150℃ | 200℃ |

| fusing point | 255-265℃ | 210-215℃ | 165-170℃ | 220℃ |

Notes: terylene can not resist concentrated sulfuric acid or heated-up formic acid, polypropylene can not resist strong oxidizing acid such as chlorosulfonic acid, aquafortis, concentrated superalkali, concentrated sulfuric acid, propionic acid, caloric aromatic hydrocarbon and so on.

In order to reach ideal filtering effect and proper filtering speed, apart from refer the above table, you should also choose the filter cloth according to the feed pulp granularity, density, viscosity chemical composition of the feed pulp and filtering technical conditions. Different woven material, and woven method will make the filter cloths different in their intensity, extensibility, air permeability and thickness, thus influences the filtering effect. What’s more, the filter medium also include cotton spinning cloth, bolting cloth, filter paper, microporous membrane and so on, please choose them according to your actual requirement. If you need this kind of technical service, please contact our filter press research institute.

3). Hydraulic system part and Electric system

Hydraulic system part composed of plunger pump and each hydraulic valve, is a power apparatus for driving pressure plate to compress and loosen the filter plate. When pressing filter plates, put down the “Press” button to start motor. In this time the electromagnetic change valve not be triggered, the plunger pump deliver oil to rear room of hydraulic cylinder. When the pressure in cylinder rising to upper limit setted on electric contact manometer, pump stops. Then oil pressure is maintained automatically. When oil pressure drops to the lower limit setted on etctric contact manometer, the plunger pump is started again, and compensate oil to hydraulic cylinder to ensure the operating pressure under 25 MPa.

After finished to feed slurry, to put down the”stop” button first, then to put down the “loose” button to start motor, And the eletromagnetic change valve changes direction, plunger pump deliver oil to foreroom of hydraulic cylinder. The piston rod take the pressing board returning, filter plates loosened. The upper and lower limit on electric contact manometer maybe adjusted according to filtering pressure. Usually we advise that the upper limited needles(red needles) on 25MPa, and the lower limited(green needles) on 20Mpa;

4). Auto. Plate separate system part

The auto.plate separate system consists of reducer, plate shifter, pushing and pulling pole and so on. The reducer will drive the chain belt and thus bring the plate shifter into movement. The shifter will be pulled apart one by one. The automatic turn-taking of the pushing and pulling board depends on time (2-3 seconds) set by time-set device connected with PLC programmer. The pushing and pulling pole on the pulling board can operate and control the halt and start during the process of pulling the board at any time in order to ensure the successful accomplishment of discharging on the plate shifter.

5). Auto. drip trays part

The drip trays system is mainly used to receive the seeping and filter-cloth-washing liquid. At the end of the filter press discharging the filtered cake, the drip trays turns close and then after the filtering, it is switched on by the electric engine and turns around again. The filtered cake is opened then. The opening angle of the downward-open plate is 50-70°. The protection method of the drip trays: the transmission of the electric engine should be regulated by the time.

6).Conveyor belt part

This part is transfer the filter cake from the filter press to outside, usually it running while the plate separate;.

2. Filter press Application:

Chemical:Dyestuff、Pigment、White carbon black、Caustic soda、Soda、Brine sludge、Black lead、Saponin、Zinc sulphate、Manganese、Ferric hydroxide、Lithopone

Metallurgy&Coal:Gold mine、Silver ore、Copper mine、Zine ore、Iron ore、Cobalt ore、Nicke ore、Uranium ore、Carbide slag、Salt lime、Raw coal、Flotation tailings

Food:Maltose、Brewers Yeast、Carragcenan、Vegetable oil、Gourmet powder、Glucose、Diastase、Corn cream style、Whitewine、Yellowwine、Soy sauce、Juice

Pharmaey:Amino acid、Intermediates、Chinese patent drugs、Blood products、Bacteriophage、Terramycin、Berberin、Aureomycin、Calcium phytate、Organophosphorus、Saccharifyingenzyme、Growth hormone

Sewage:Printing&dyestuffsewage、Tannery sewage、Smelting sewage、Brewing sewage、Pharmacy sewage、Plating sewage、Chemical sewage、Papermaking sewage、Electrolysis sewage、Mining sewage、Dung sewage、Port sludge

Non-Metallie Mines:Kaolin Clay、Swel1soil、Electrical Ceramics、Converter mud、Granite flour、Activated clay、Porcelain clay、Phosphorus Ore、Industria1 sand