The difference between 3kinds of useful filter press: the PP Chamber filter press, Membrane filter press and PP Plate&frame filter press; The biggest difference is filter plate; Including the structure of the filter plate, feeding type, feeding pressure , feeding temperature and application etc., the main control mode is basically the same; here we explain in detail the differences in each aspect.

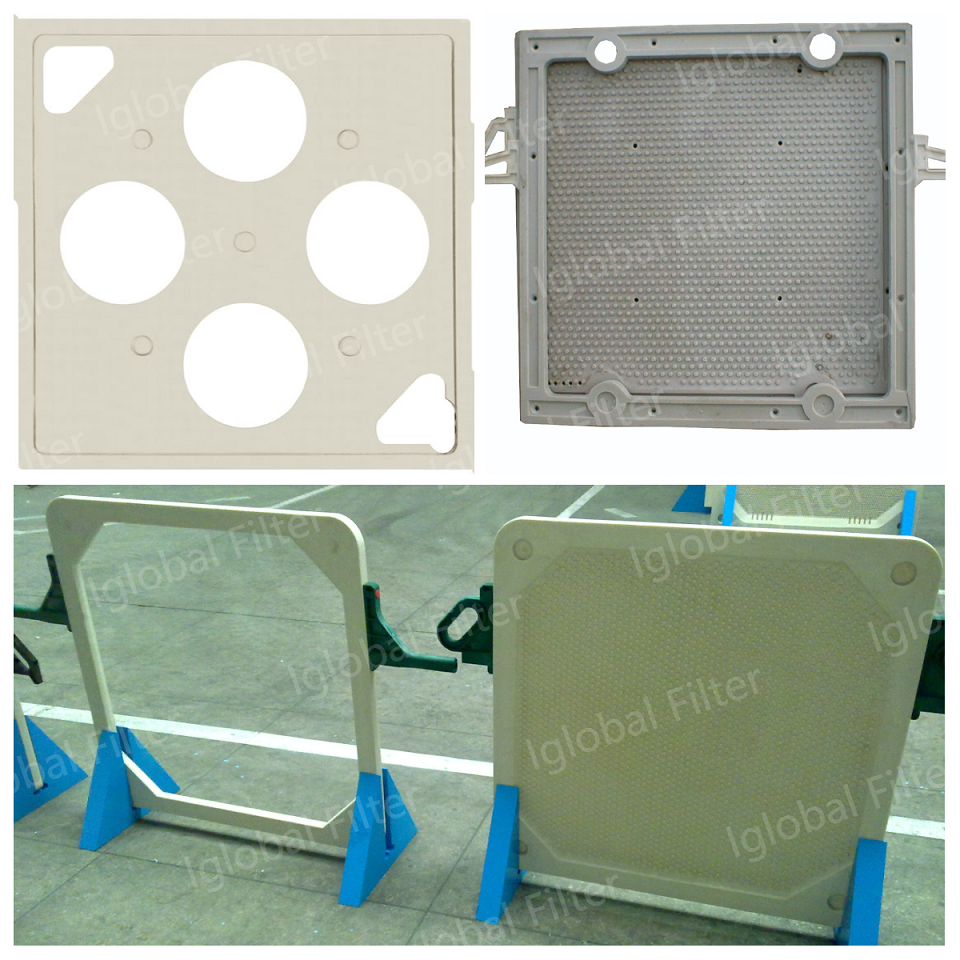

PP Chamber filter press(some times we also called recessed filter press)

This type of filter press is currently the most popular, but also the most used, its filtration part is mainly composed of chamber plate, each chamber plate is the same shape, two chamber plates to form a filter chamber unit; the thickness of each chamber plate in the 50-100mm (according to the size of the filter plate and the actual needs of the customer’s requirements to produce)

The feeding methods are also abundant, from the upper feeding, middle feeding, lower feeding, corner feeding, outside the plate feeding and so on;

The temperature resistance can reach up to 120 degrees Celsius and the feeding pressure can reach 40bar;

The machine can be used in various fields, is a simple operation, cost-effective equipment.

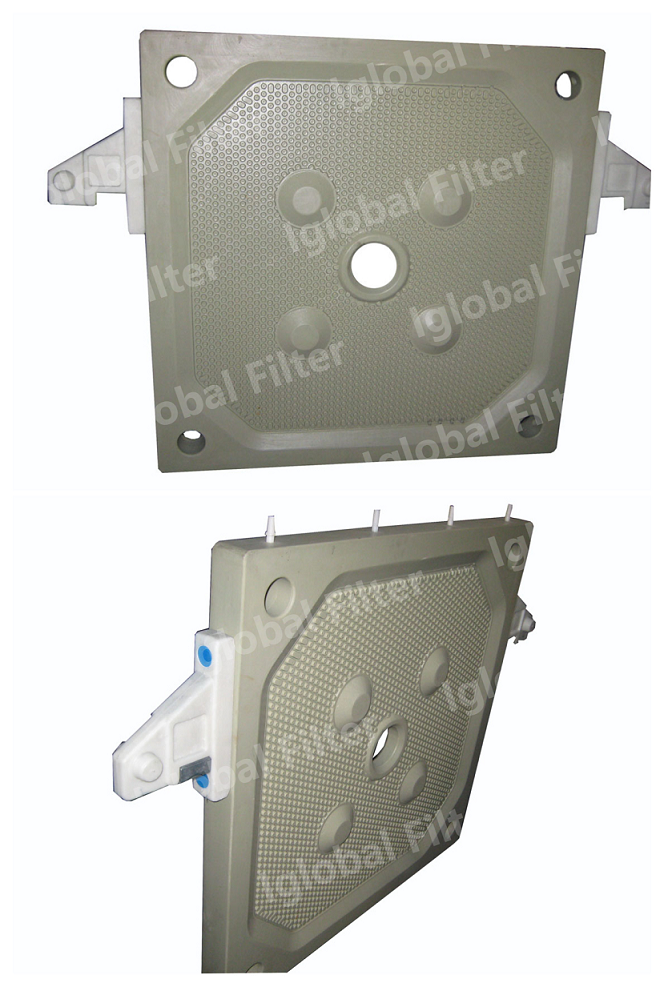

Membrane filter press

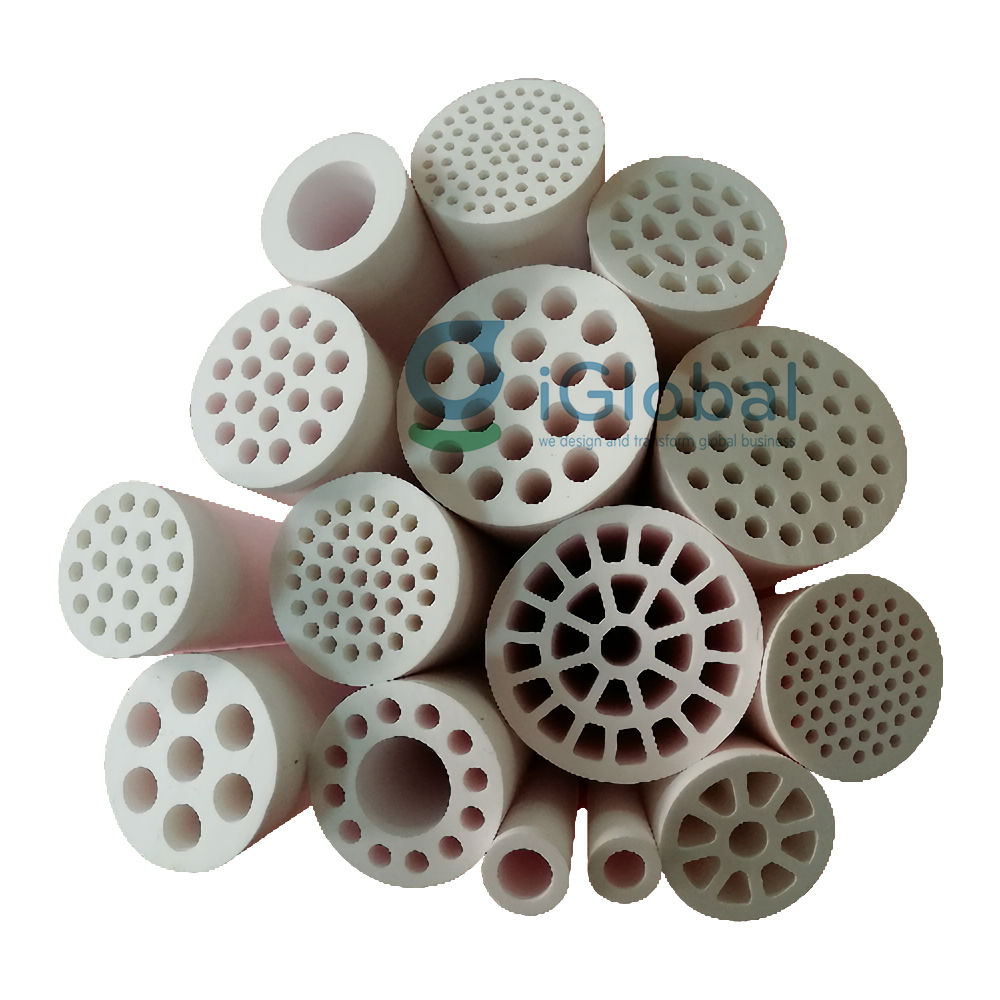

This filter press can be said to be developed on the basis of chamber filter press, its filter part is composed of chamber plate and membrane plate;

The membrane filter plate is mainly composed of the main body of the filter plate and the membrane, if the membrane is double-sided, the filtration part arrange is: a chamber plate + a membrane plate + a chamber plate + a membrane plate. If the membrane is a single-sided, means the shape of each membrane filter plate is same, so the arrange list is same as chamber filter press type;

At present the material of membrane has two kinds: rubber and PP, the elasticity of rubber membrane is good, the price is cheap, but the shortcomings of rubber is acid and alkali resistance, feeding temperature and pressure are strictly limited; for example, the squeezing pressure is generally lower than 10bar; but the PP membrane in this item is less restrictive, the highest squeezing pressure of can be up to 100bar.

The feeding methods of this model are as varied as chamber filter press, which can be up-feeding, centre-feeding, down-feeding, corner-feeding, out-of-plate-feeding, and so on.

In practice, the membrane filter press has one more squeezing function than chamber filter press, but the moisture content of the cake of membrane filter press can be 15-40% lower than chamber filter press (different slurry will have different effects).

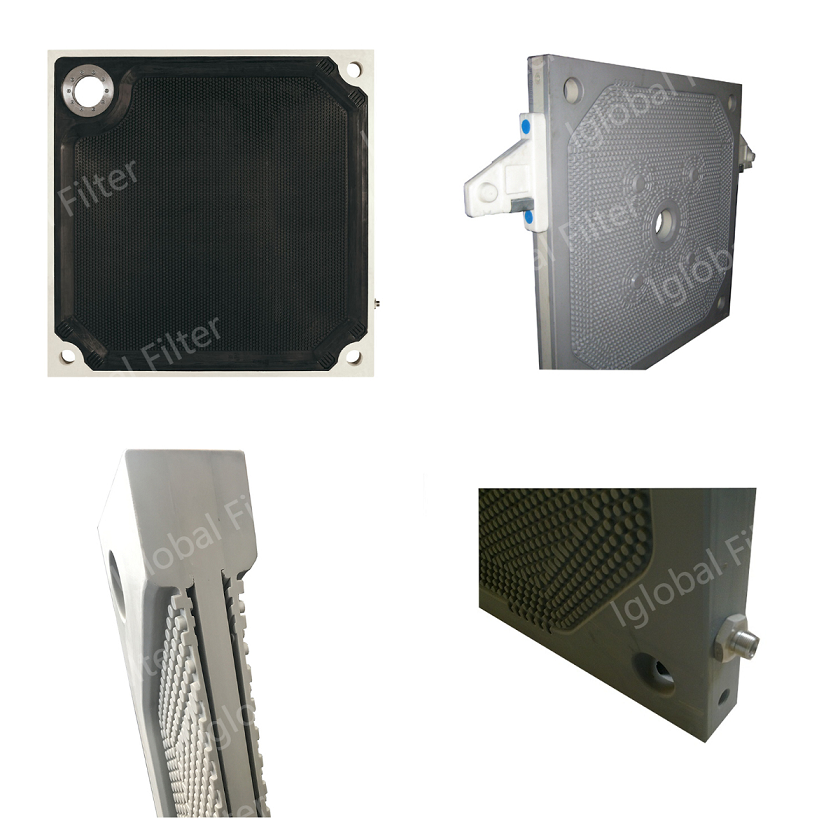

PP Plate&frame filter press

This kind of filter press is the oldest type, its filtration part is composed of a plate and a plate frame, the plate no chambers and space for the solid, only for filter, the solids remain in the frame, forming a cake; arrange like a plate + a frame + a plate + a frame ……

The thickness of the plate and frame is generally thinner than that of the chamber plate, so the pressure resistance is generally lower than 6 bar.

The feeding method of this model is relatively single, can only be corner feeding or outside the plate feeding;

Now this model filter is gradually eliminated from the market, generally mainly used in some industries with low solid content, such as chemical fibre wastewater and part of the chemical industry;