PRODUCTION INTRODUCTION

UF Membrane IGFUF160-OP-PVDF series pressure ultrafiltration film uses imported PVDF raw materials with filtering accuracy of 0.1 microns to ensure that the turbidity of the water out of the water is ≤1NTU; the external pressure structure is suitable for raw water with high turbidity and high suspension content; Can be used for air brushing and reflux gas, greatly improving the anti -pollution capacity of the membrane. PVDF external pressure membrane has a small pressure difference during operation, which can reduce energy consumption and save operating costs.

The advantage of IGFUF160-OP-PDF

- IGFUF160-OP-PVDF ultrafiltration membrane is one of the ultrafiltration components series of strong chemical corrosion. PVDF material is widely used in many sewage and wastewater treatment fields due to its strong anti-pollution characteristics;

- IGFUF160-OP-PVDF Ultrafilled PVDF material itself has good pollution resistance. Because PVDF is a fluoride polymer material, the chemical stability of PVDF membrane material is extremely stable. It

- IGFUF160-OP-PVDF film can be cleaned to the membrane surface pollutants through strong acids and strong oxidants in the field of pollution and wastewater.

- The material of the IGFUF160 -op-PVDF membrane component has super toughness. The elongation of the membrane thread is as high as 100%or more, and the long-term low-pressure operation is not easy to break the wire;

- IGFUF160-OP-PVDF film component adopts a stainless steel staller to connect the shell and end cover, which has stronger pressure.

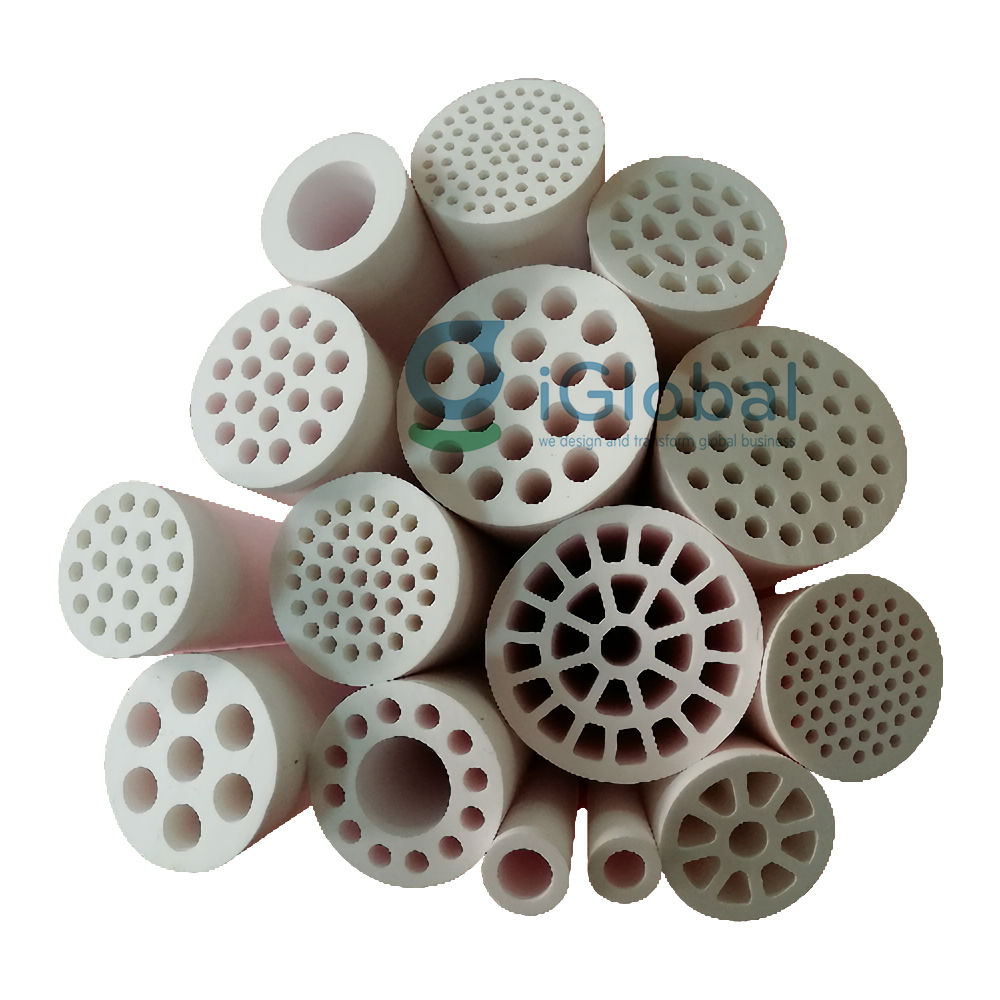

MEMBRANE FIBER FEATURES:

Excellent physical and mechanical properties:

The tenacity of the membrane filaments is high, and the tensile rate is more than 100% . It is suitable for water-making by air-water mixing, backwashing by air-liquid mixing and chemical cleaning by aeration, the high toughness ensures that PVDF membrane filaments are not easy to break when they are impacted, and ensures the stability of membrane properties and effluent water quality.

Excellent chemical corrosion resistance:

The maximum residual chlorine tolerance of membrane filaments can reach 5000 ppm, which can be widely used in various harsh water quality conditions and operating conditions requiring high concentration of oxidant, prolong the service life of the membrane.

Strong anti-pollution ability:

The polarity and surface smoothness of the membrane filaments are improved by using international high-quality raw materials, advanced membrane formulation and technology, which makes the surface of the membrane filaments not easy to adhere to pollutants, reduces concentration polarization, and enhances anti-pollution performance.

High hydrophilicity and low energy consumption:

The hydrophilic polymer material was used to blend and modify the membrane filaments, so that the membrane filaments had permanent hydrophilic modification effect, and the water production was close to 0 pressure, with very low trans-membrane resistance and lower energy consumption, and the fouling of the membrane by organic matter was reduced, the cleaning frequency is reduced, and the use is convenient and the service life is prolonged.

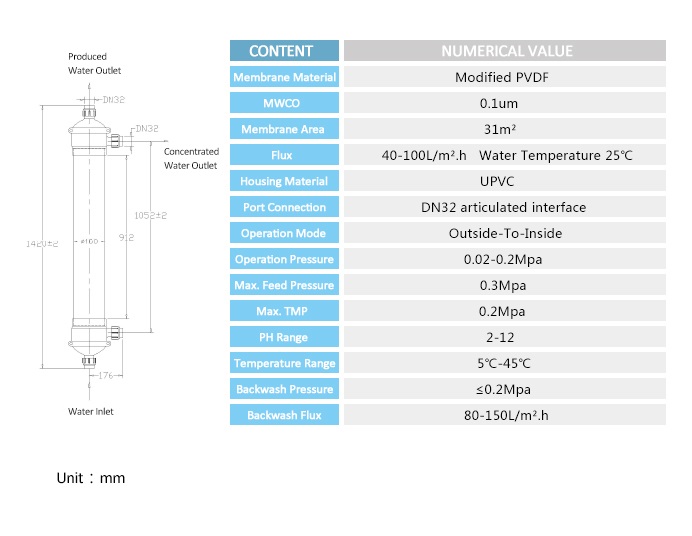

PRODUCT DRAWING