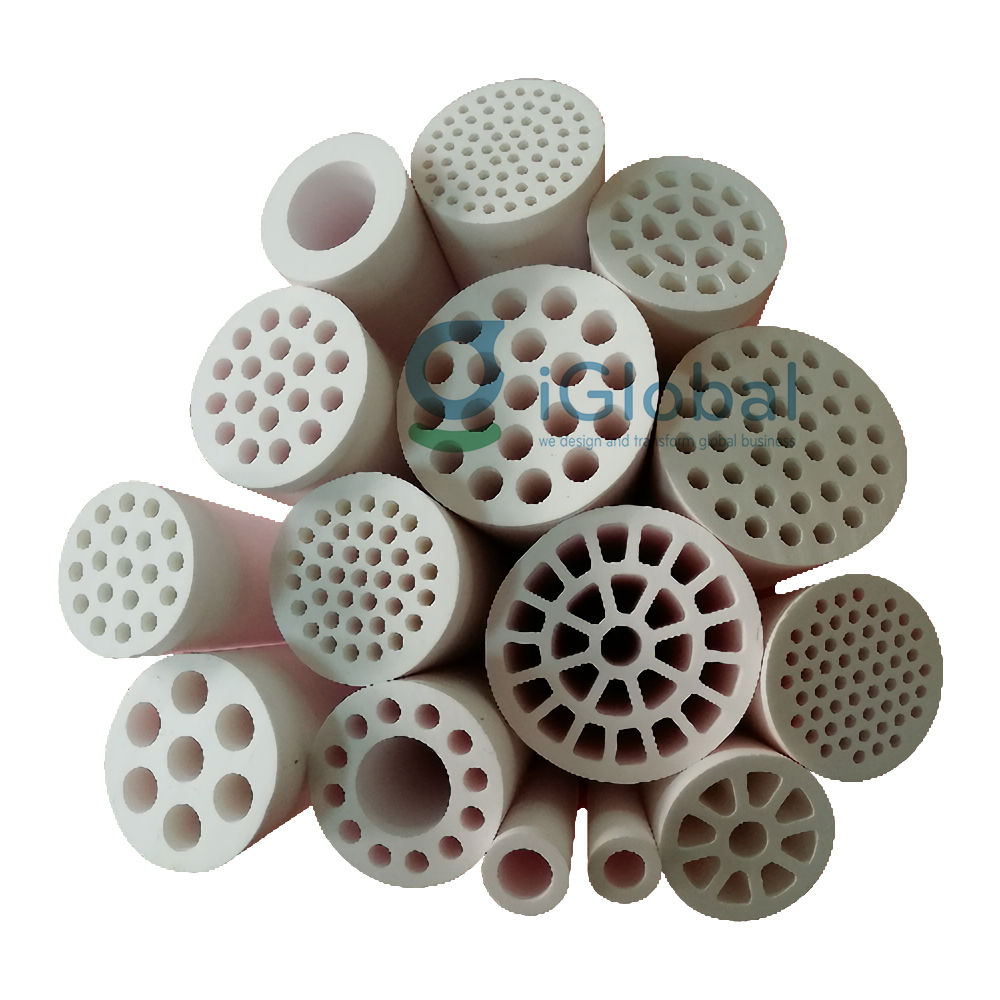

IGF-LMBR Series Hollow Curtain Membrane is a new water treatment process that combines traditional industrial and membrane separation technologies. It has the following characteristics:

1, IGF-LMBR Series Hollow Curtain Membrane is an organic combination of membrane separation technology and biotechnology (mainly activated sludge method). The MBR process replaces the traditional activated sludge method’s secondary sedimentation tank and conventional filtration unit with ultrafiltration membrane or microfiltration membrane separation technology, improving biochemical efficiency and effluent quality.

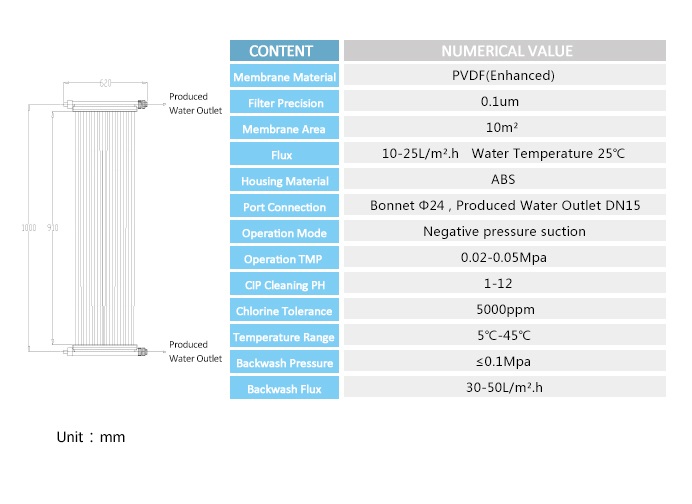

2, IGF-LMBR series Series Hollow Curtain Membrane use PVDF material membrane filament processed by the international advanced membrane technology, strong oxidant, strong acid tolerance, can withstand frequent high concentration of chemical cleaning, so that the flux in time to restore, prolong the service life of the membrane ;

3, IGF-LMBR series Series Hollow Curtain Membrane with a unique production process to enhance the stretch rate and mechanical strength of the PVDF membrane filament, so that the membrane filament in the MBR membrane pool even if there is a large stretch does not easily produce broken filament, to ensure the stability of the water quality.

4, IGF-LMBR series membrane filament skin layer using hydrophilic modified groups, enhance the hydrophilic performance of the membrane filament to water molecules, so that the MBR membrane filament has the characteristics of not easy to adhere to pollutants, that is, pollutants are not easy to adhere to the surface of the membrane filament; work, for a small amount of adhering to the surface of the membrane pollutants, the membrane filament itself shaking with the aeration process, so that the pollutant particles are easy to fall off the surface of the membrane, so as to maintain the MBR This maintains the stability of the water production of the system.

Application:

Municipal sewage upgrade

integrated water treatment equipment

industrial wastewater upgrade

Refuse leachate treatment

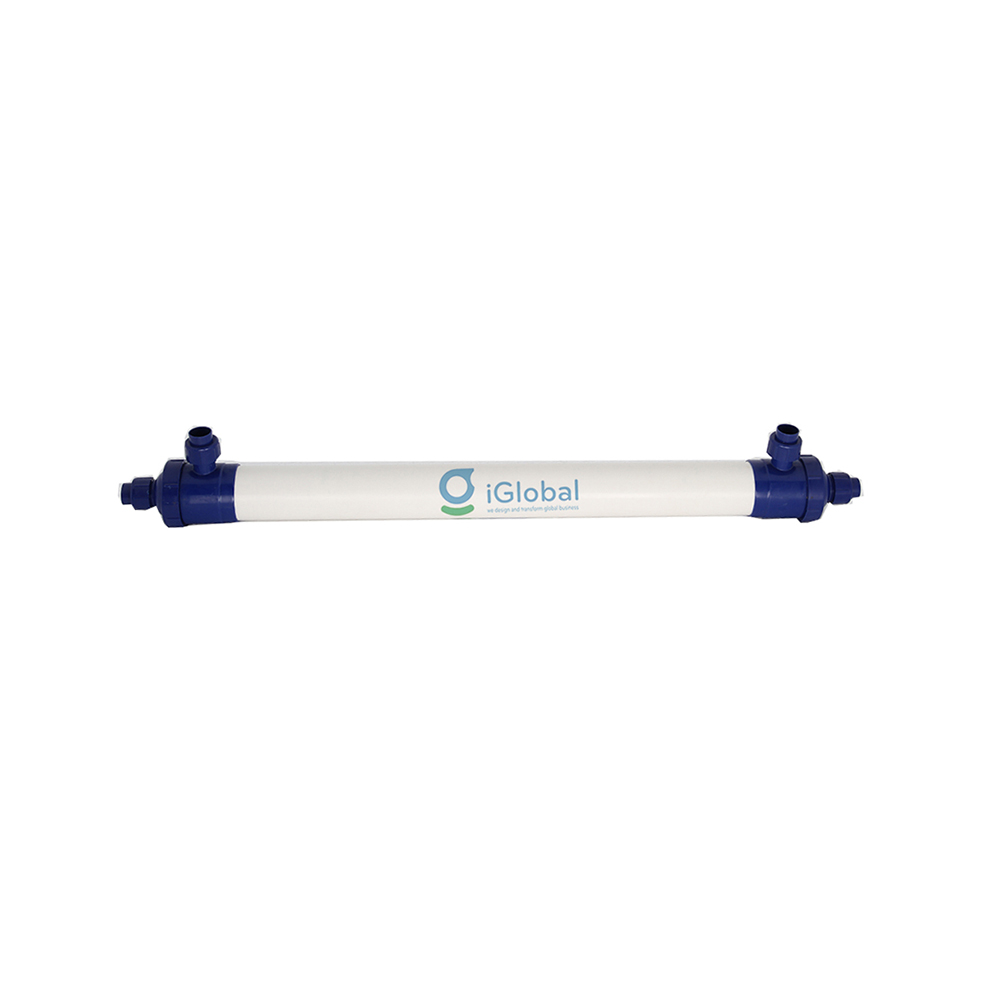

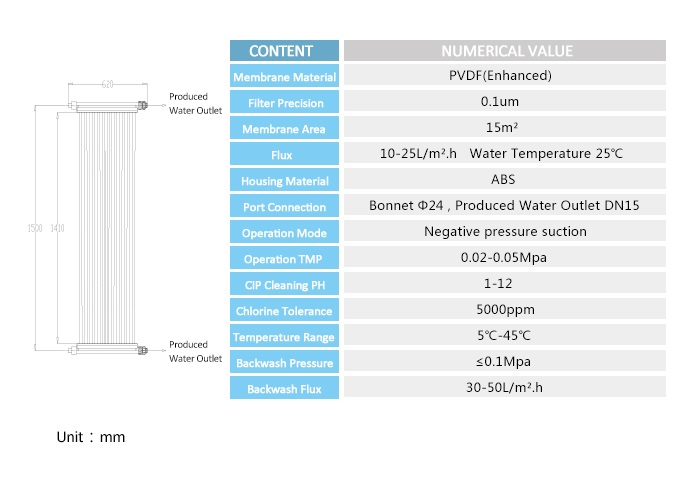

Product Drawing:

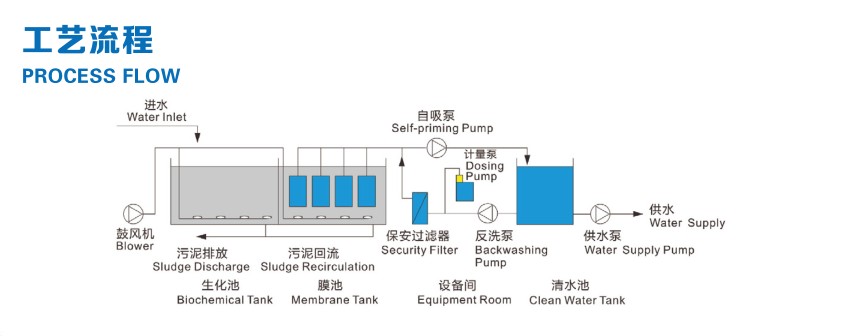

Process Flow