Introduction

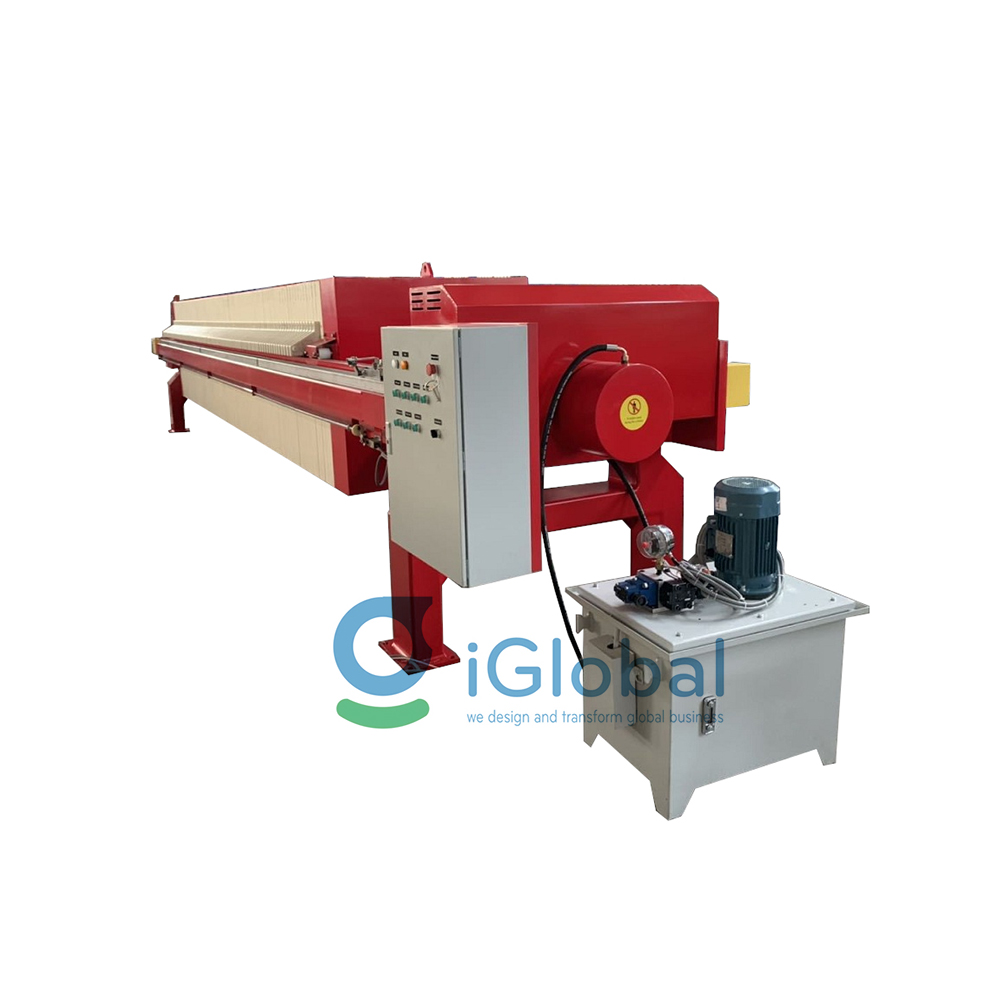

Large capacity PP filter press is an intermittent filer equipment use for solid-liquid separation of fluid suspensions of all kinds, with its wide application fields and good separation effect, they are widely used in technical processes such as petroleum, petrochemical, dyeing, metallurgy, pharmaceutical, foodstuff as well as different fields such as textile, printing and dyeing, pharmacy, paper making, where solid-liquid separation such as waste water treatment is needed.

With its design integrated with engine, electricity and liquid as a whole, the machine is reasonable in structure, easy and reliable for operation, convenient for maintaince. Each working procedure such as auto. feeding, auto. drip trays. plate shaking, core blow, cloth washer, cake washing and blow, auto. plate separate system can all be realized through the machine. The volume of the filtering chamber is adjustable so that it can deal with the suspended substance even in the form of tiny and sticky grains. The filter plate is formed by die pressing of the reinforced polypropylene plastic. Framework has strong intensity to make sure long service life. This machine is really your ideal choice.

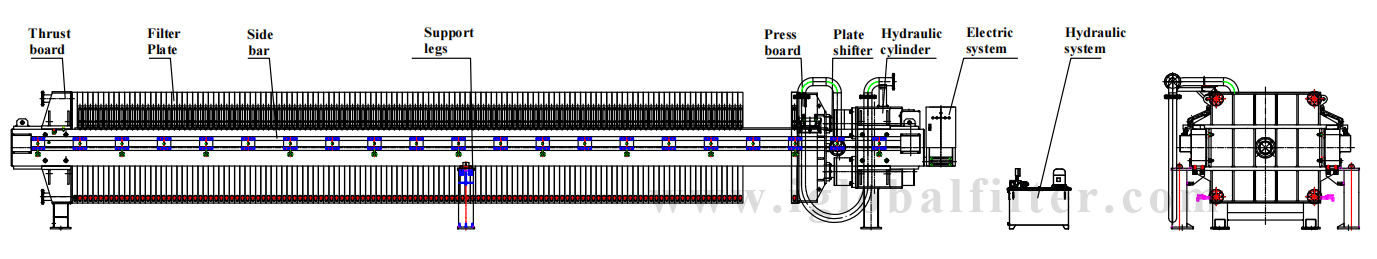

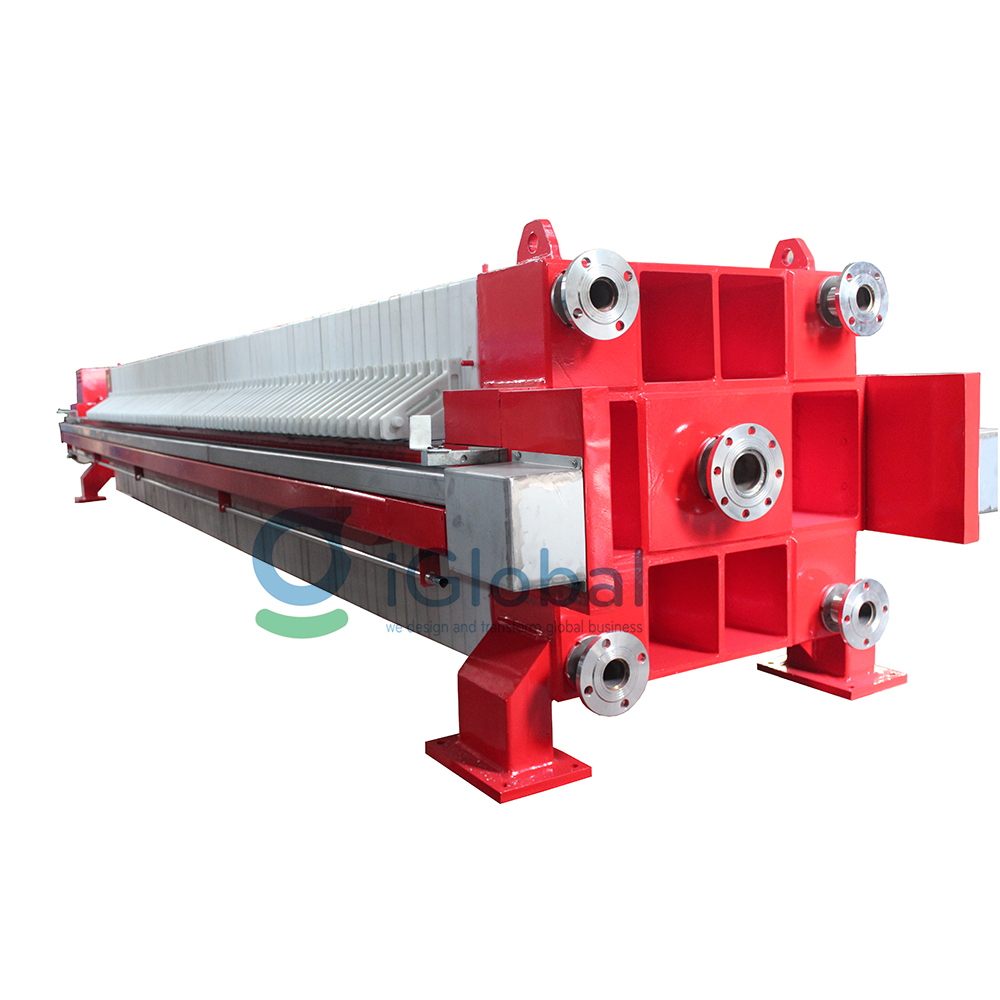

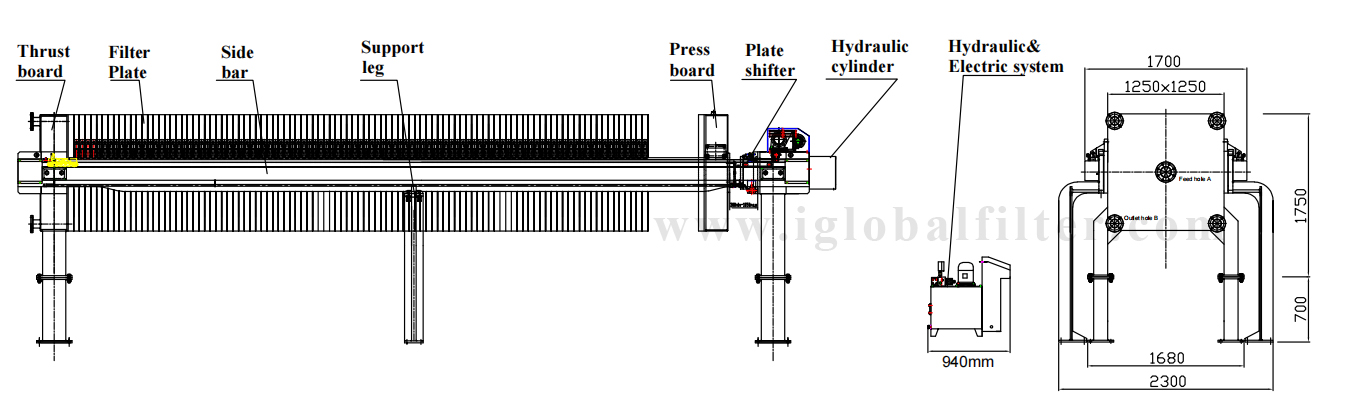

Standard model of large capacity filter press consists of Four parts: press frame, filtering parts, hydraulic and electric system, auto. plate separate system:

Part 1: Press frame

Press frame is the base of the whole machine, used for supporting filter mechanism and connecting other parts. It is mainly composed of thrust plate, pressure plate, oil cylinder body and main girder. When the machine is under working, piston inside oil cylinder body will push on the pressure plate to compact the filter board, filter cloth and rubber diaphragm between pressure plate and thrust plate, so as to make sure the feed pulp can be filtered in the filtering chamber.

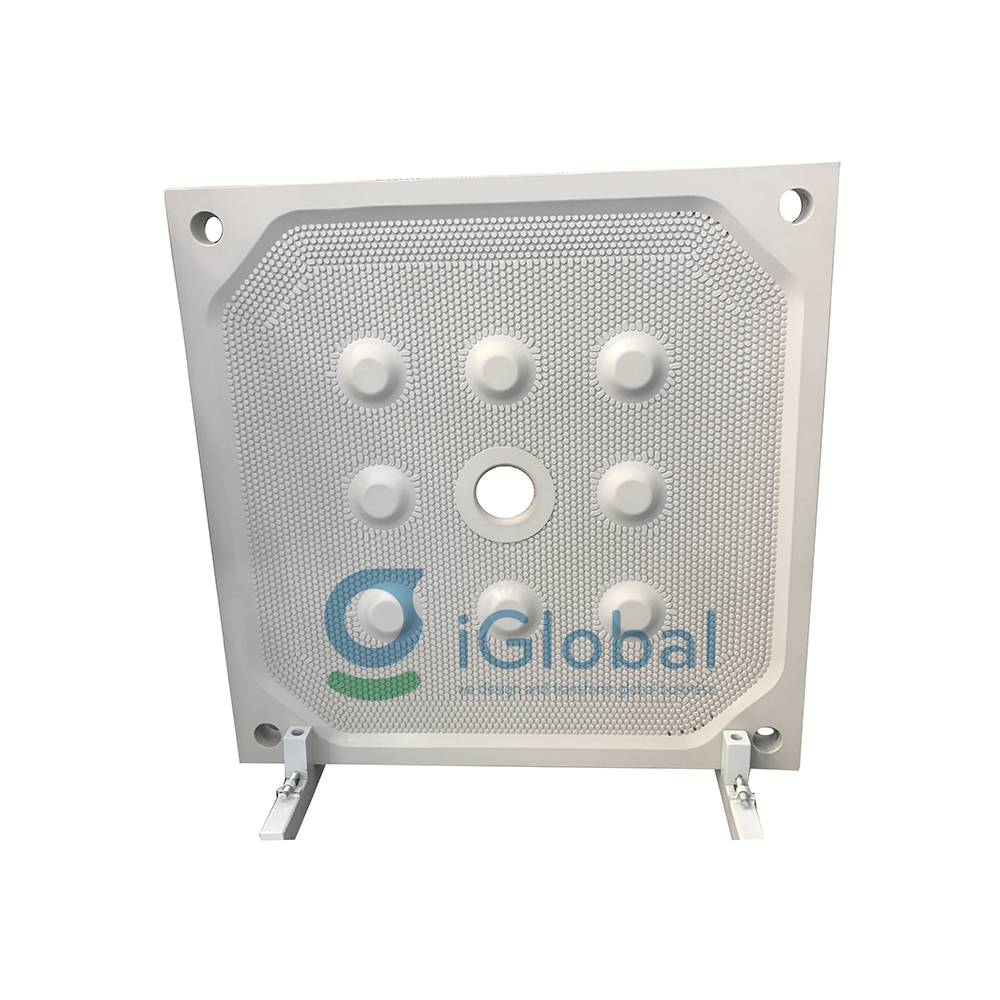

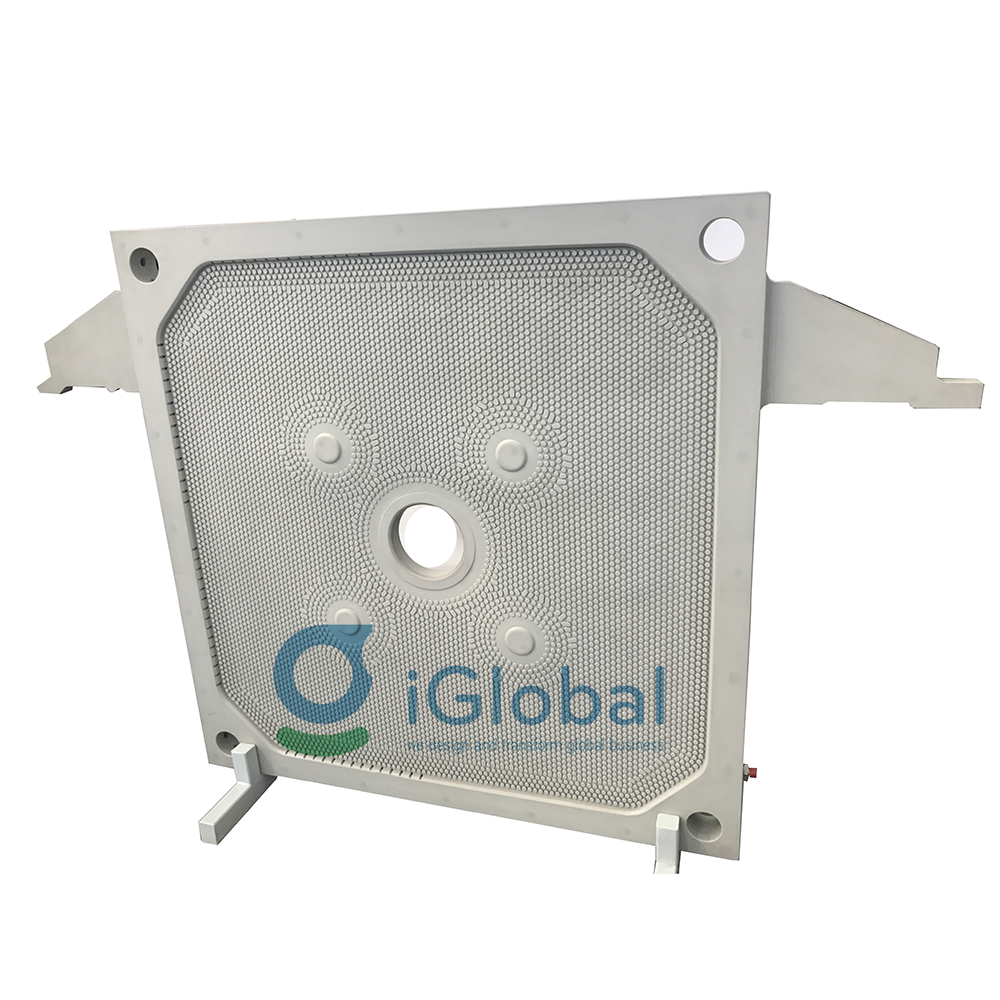

Part 2. Filtering parts

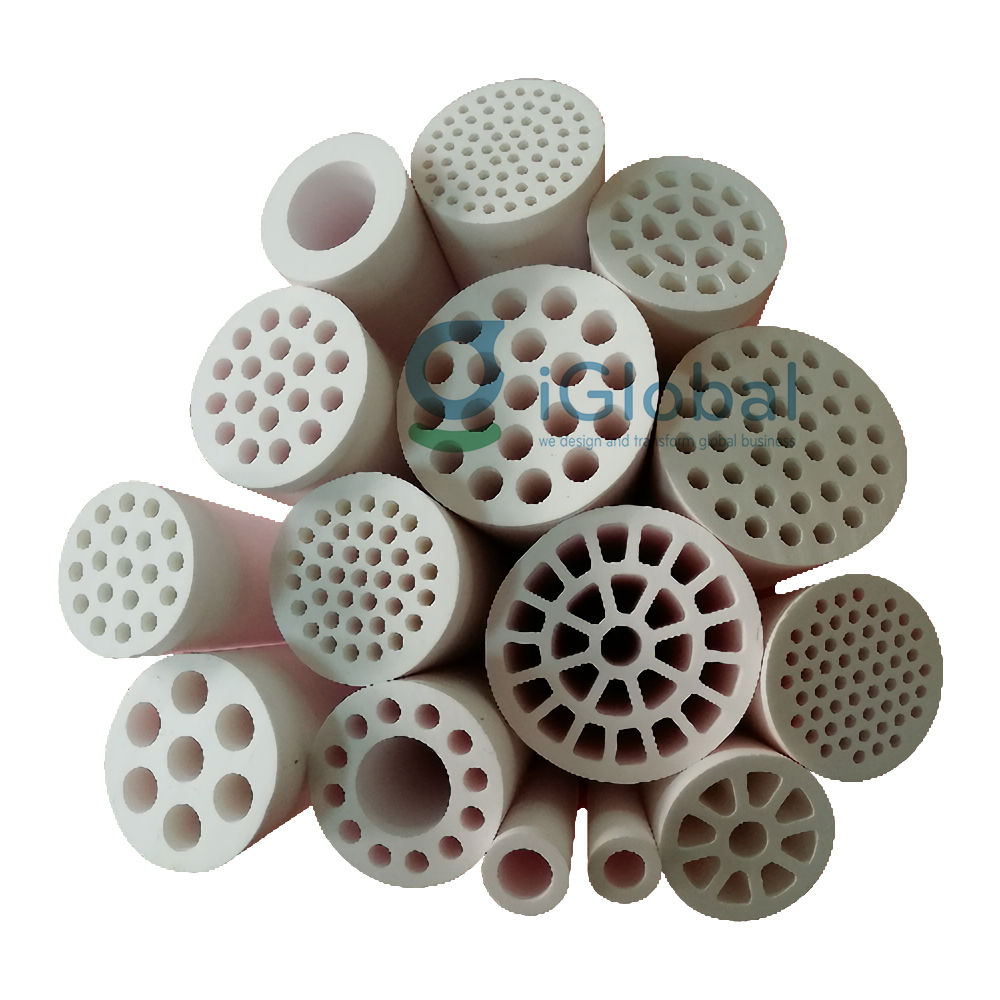

Filtering parts consist of filter plates(PP recessed plate or membrane filter plate) and filter cloth . The interlacing arrangement of filter plate and filter cloth form filtering unit-filter cells one after another. At the beginning of filtering, feed pulp is pushed on by material charging pump into each filter cell through the charging mouth on the thrust plate, there solid-liquid separation is carried out by the pressure produced by charging pump. The solid matters will remain in the filter cell to form filter cake due to the filter cloth while filtrate will be discharged through nozzle or pipes. If the filter cakes need to be washed, water can be let in through the washing mouth on the thrust plate to infiltrate through the filter cakes. Similarly, if you want to get filter cakes with low moisture content, let in compressed air through the washing mouth of the thrust plate to infiltrate through the whole filter cakes layers, to bring away part of water in them (applicable for Uk Model Machine). If choose PP membrane plate, squeezing the filter cake by water or compressed air to get more lower moisture filter cake.

Part 3. Auto. plate separate system

The plate separate system consists of motor, plate shifter, pushing and pulling pole and so on. The motor will drive the chain belt and thus bring the plate shifter into movement. Filter plate will be separate one by one or 3 or 5plates open one time. The automatic turn-taking of the plate separate depends on time (2-3 seconds) set by time-set device connected with PLC programmer. The pushing and pulling pole on the pulling board can operate and control the halt and start during the process of pulling the plates at any time in order to ensure the successful accomplishment of discharging on the pulling plate.

Part 4.hydraulic and electric system

Hydraulic &electric system composed of oil pump, each hydraulic valve and PLC control panel, is a power and control center to the whole filter press.

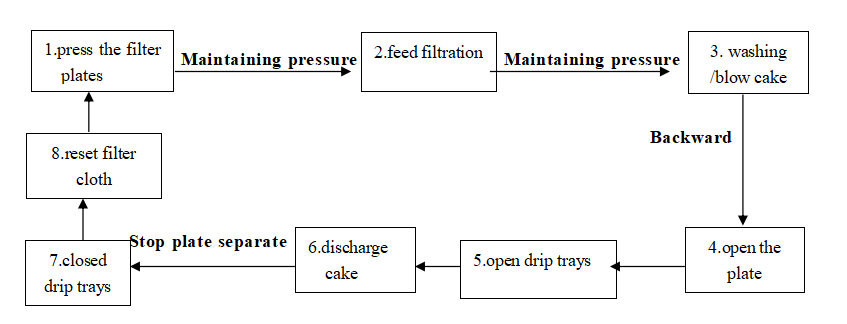

Operating procedue(with drip trays system)

Technical data

1250*1250mm series

| Filter area(m2) | 100 | 120 | 140 | 160 | 180 | 200 | *220 | *240 | *260 |

| Capacity(L) | 1570 | 1890 | 2125 | 2435 | 2750 | 3050 | 3380 | 3620 | 3940 |

| Machine Length(mm) | 6000 | 6510 | 6875 | 7350 | 7840 | 8400 | 8915 | 9300 | 10350 |

The ” * ” the press frame equip middle support leg

Assemble drawing

1500*1500mm series

Technical data

| Filter area(m2) | 200 | 250 | 280 | 300 | 340* | 400* | 450* | 500* | 560* |

| Capacity(L) | 3555 | 4370 | 4920 | 5330 | 6000 | 7000 | 7940 | 8760 | 9800 |

| Machine Length(mm) | 6770 | 7610 | 8170 | 8590 | 9290 | 10270 | 11250 | 12090 | 13350 |

The ” * ” the press frame equip middle support leg

Assemble drawing