Small capacity PP filter press is advanced seperation machinery products integrated in its design with engine, electricity and liquid as a whole. Standard model filter press consists of Four Main Parts: machine frame, filtering parts (filter board, filter cloth ), hydraulic system part, and electrical control part. What’s more, PP squeezing system or auto. drip trays device can be added according to customer’s requirement.

Features:

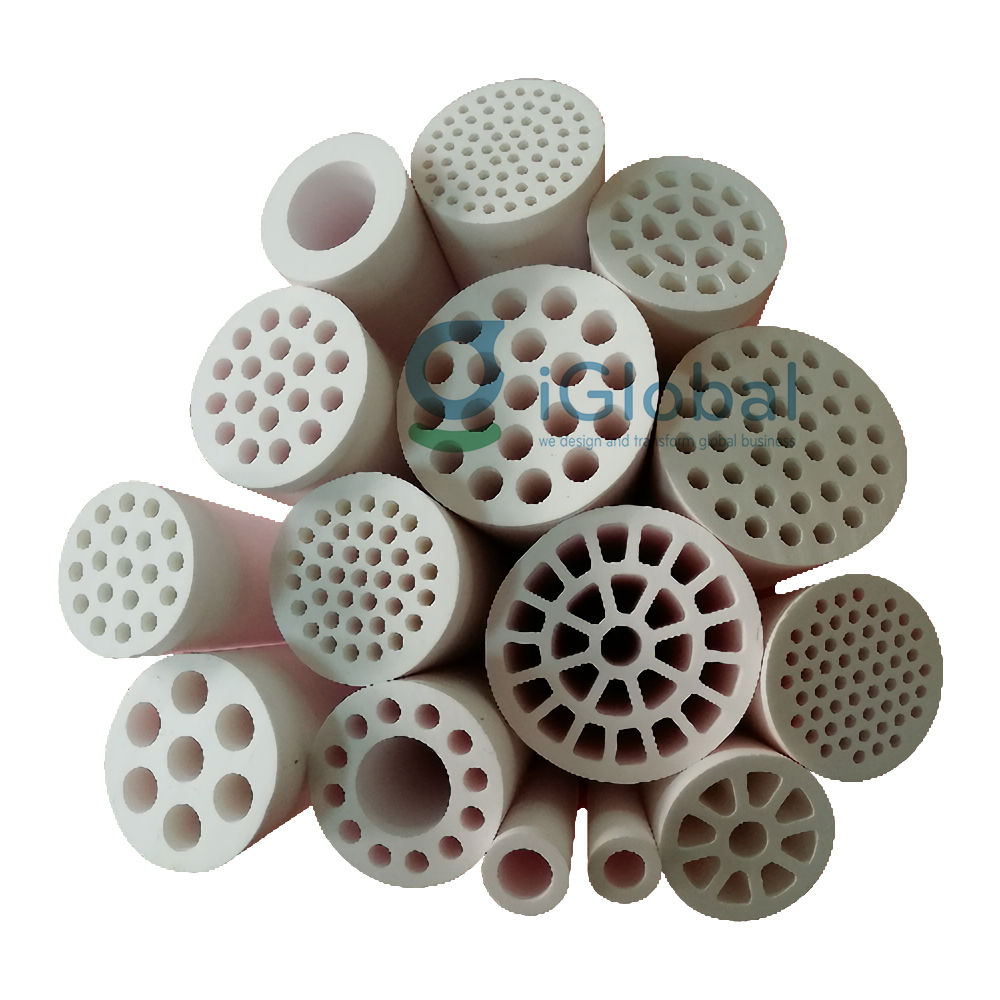

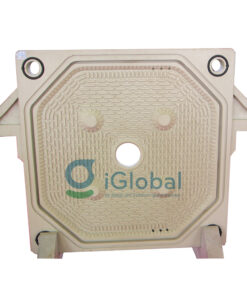

1. Adopting the patent techniques, Moulding processthe reinforced polypropylene into chamber plate featuring high intensity, light weight, anti-corrosion, acid and alkaline resistant, poison-less and smell-less

2. The supporter is of welded steel structure with high strength for stress caused by cake weight and high pressure;

3. Adopting auto. hydraulic system(auto. open and closed)with auto. maintaining pressure system, and the max. pressure is 20Mpa to ensure the excellent sealing performance during filter;

4. Press the button on the electrical control board equipped with safe device to ensure safety to operators.

Application:

Solid-liquid separation of suspensions of all kinds, prevent fruitful in a wide spectrum of industries such as coal, petrochemical, metallurgy, pharmaceutical, light industry, food processing and textile, as well as environmental protection.

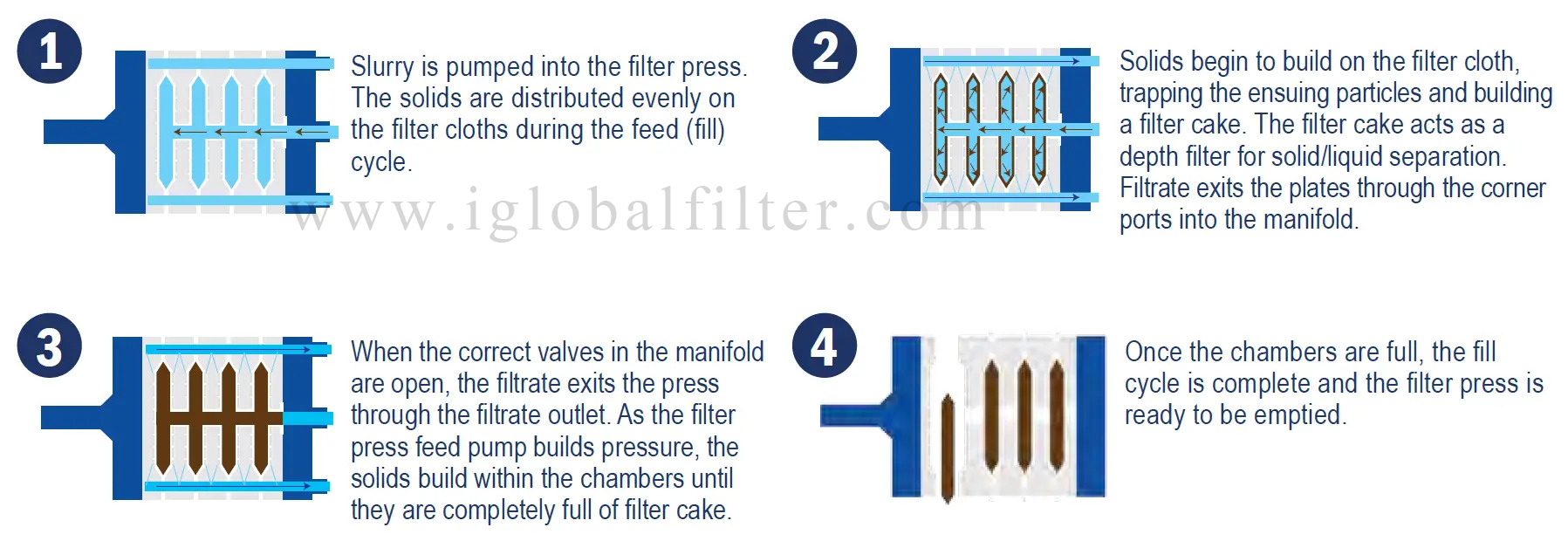

Operating principle

500*500mm filter press technical data:

| Filter area(m2) | 4.0 | 6.0 | 8.0 | 10 | 12 | 14 |

| Capacity(L) | 50 | 75 | 100 | 125 | 150 | 175 |

| Machine Length(mm) | 1900 | 2160 | 2410 | 2670 | 2920 | 3180 |

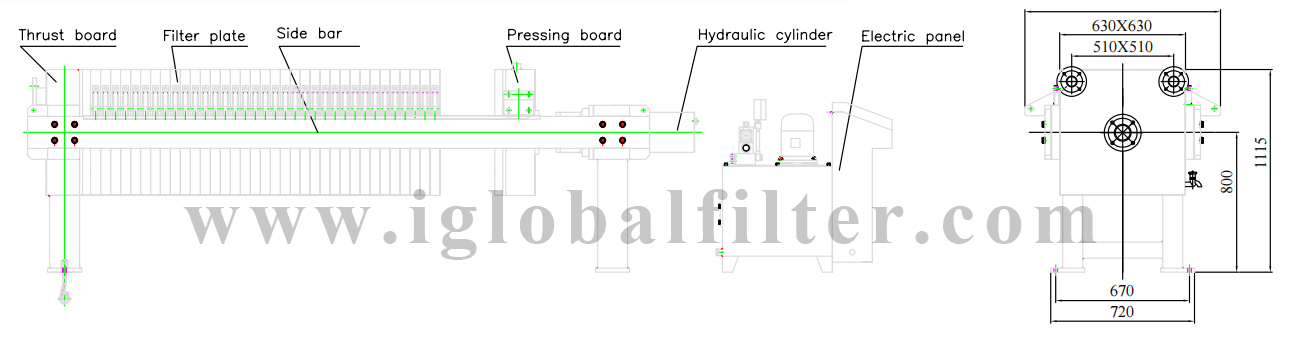

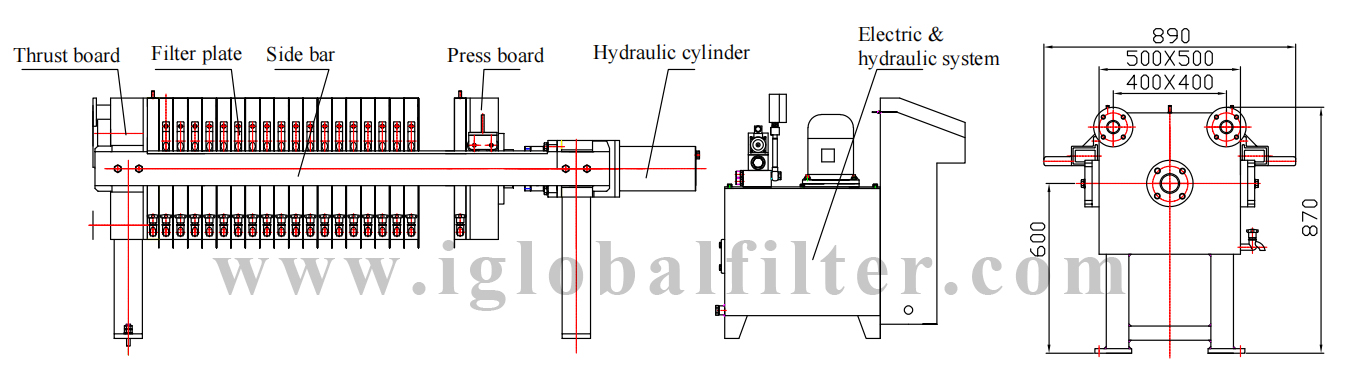

Assemble drawing

630*630mm filter press technical data:

| Filter area(m2) | 8.0 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 28 |

| Capacity(L) | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 313 | 350 |

| Machine Length(mm) | 2600 | 2760 | 2910 | 3120 | 3270 | 3420 | 3580 | 3985 | 4240 |

Assemble Drawing