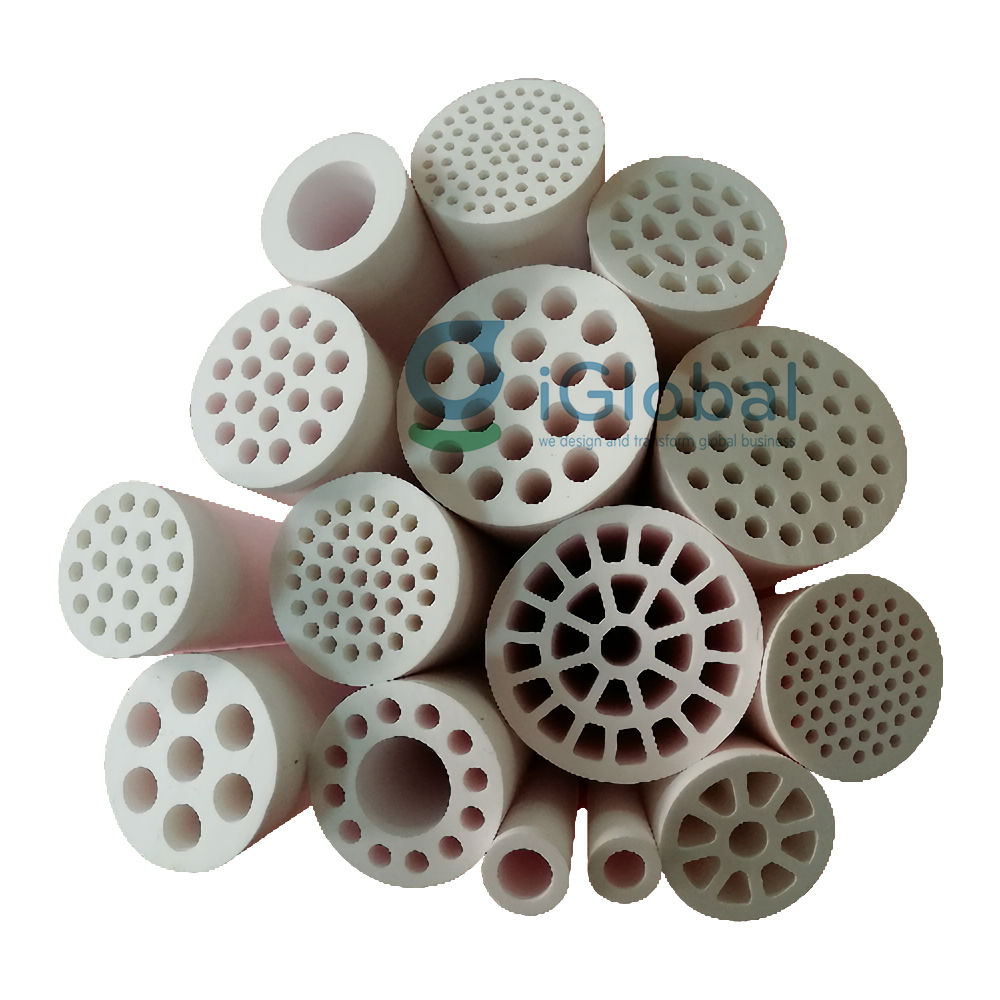

I.Ceramic membrane filter elements:

PRODUCT INTRODUCTION

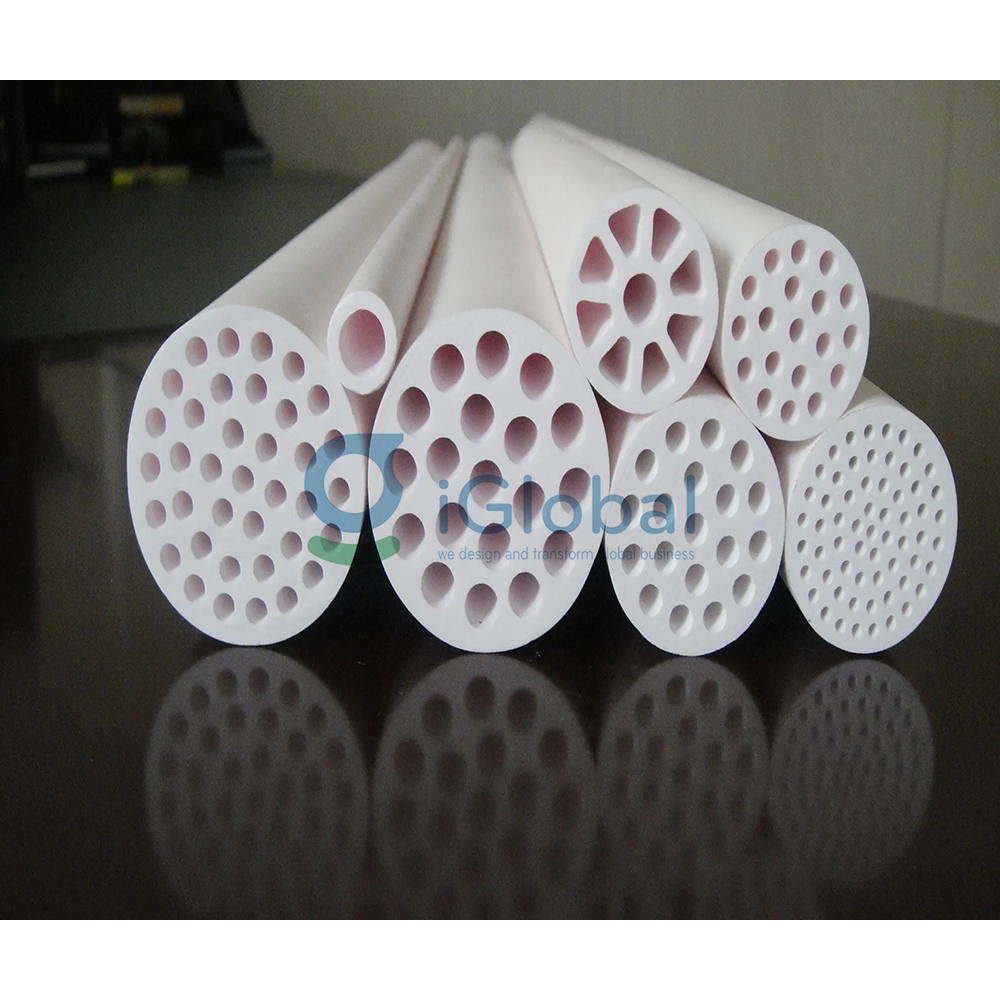

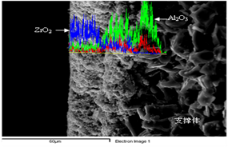

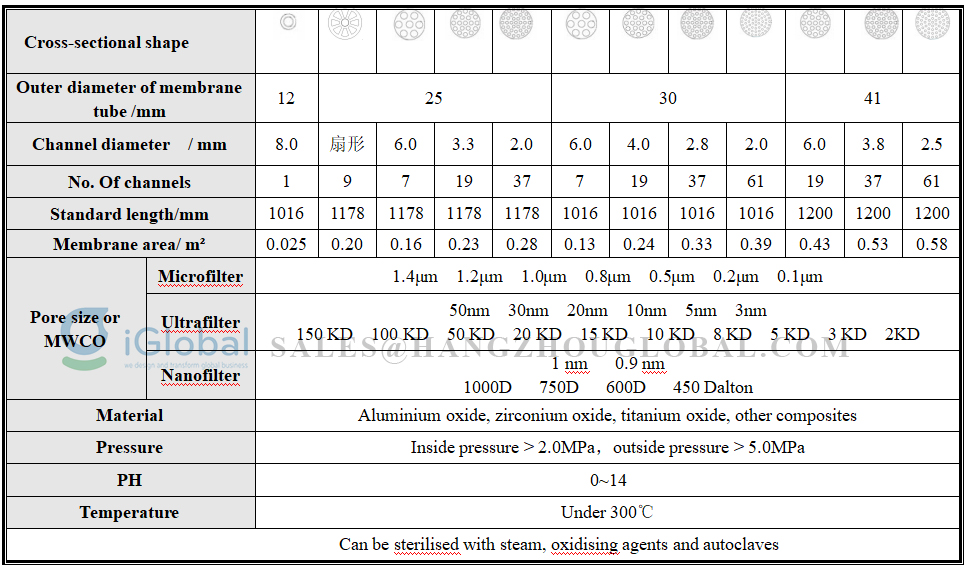

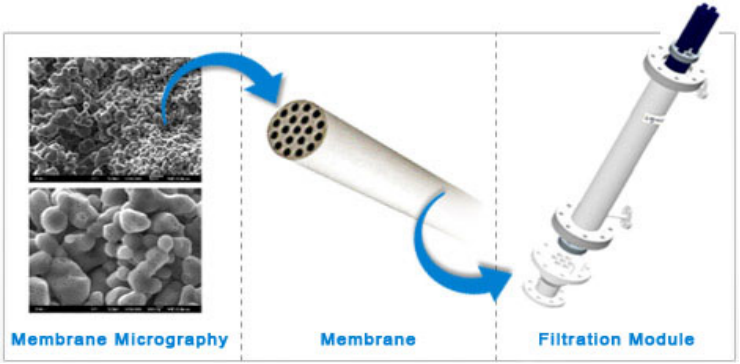

Inorganic ceramic membranes are precision ceramic filtration materials with porous structure made of alumina, titanium oxide, zirconium oxide, etc. by high temperature sintering.

The porous support layer, transition layer and microporous membrane layer are asymmetrically distributed, and the filtration precision covers microfiltration, ultrafiltration and nanofiltration.

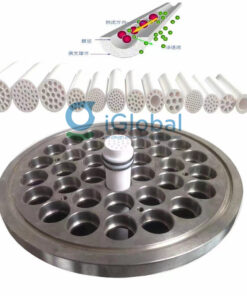

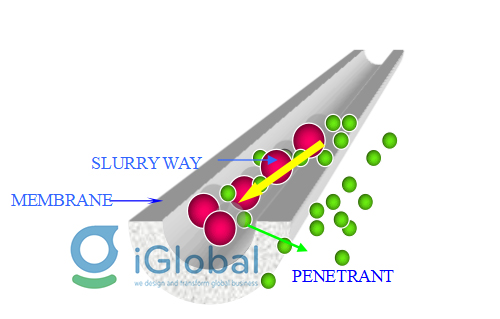

Ceramic membrane filtration is a form of “staggered flow filtration” fluid separation process: the raw material liquid flows at high speed in the membrane tube, the clarified permeate containing small molecules is driven by pressure to pass through the membrane in the vertical direction, the turbid concentrate containing large molecules is retained by the membrane, so that the fluid can achieve the purpose of separation, concentration and purification.

SEM PHOTO STAGGERED FLOW FILTRATION SCHEMATIC

PRODUCTS ADVANTAGES

Inorganic ceramic membranes, founded on the science of inorganic materials, have the following advantages over traditional separation media and equipment such as plate and frame filter, centrifuges, diatomaceous earth and polymer membranes:

*Chemically stable, resistant to acids, alkalis and oxidation

*Resistance to organic solvents.

*Resistance to high temperatures.

*High mechanical strength and good abrasion resistance.

*Narrow pore size distribution, high separation accuracy, up to nano-level filtration.

*Easy to clean, can be disinfected in-line or at high temperature, can be backwashed.

*Long service life,3 to 5 years for generally ceramic membranes

TECHNICAL DATA

II. Ceramic membrane housing and module

PRODUCT INTRODUCE

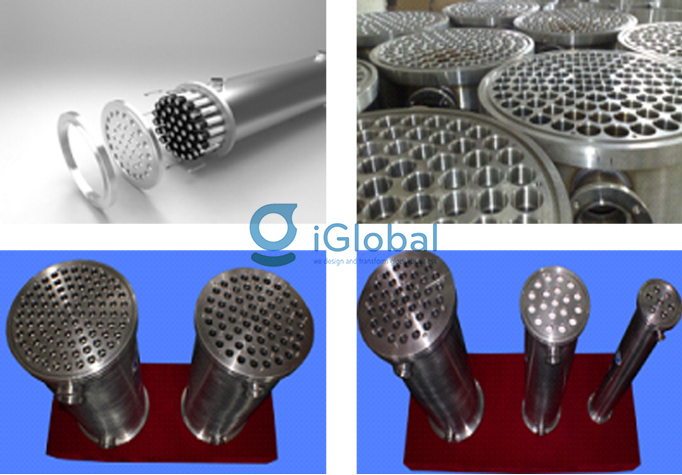

Ceramic membrane modules are pressure-resistant housings for assembling ceramic membrane elements. Depending on the needs of industrial production, ceramic membrane elements with different external diameters and different areas can be centrally filled by means of different sizes of membrane module housings. The shape and sealing design of the membrane modules are essential for the long-term stable operation of the ceramic membrane system.

Ceramic membrane modules, with different series of specialised designs, can be adapted to the special requirements of the process in different fields and ensure the qualification requirements for specialised production. The membranes are available in a range of sizes from 0.01 m² to 100 m².

ASSEMBLE DATA

Number of membrane elements filled: 1, 3, 5, 7, 12, 14, 19, 37, 61, 91, 99, 138, 349 cores

Matching membrane element length: 250 to 1200mm / OD 12, 25, 30, 40, 41mm

Body material: SUS304, SUS316(L), titanium, UPVC, FRPP

Seal material: EPDM, Fluoroelastomer, Silicone rubber, NBR, etc.

interface form: flange, clamp, live connection / DN15 ~ DN800

Nominal pressure: 1.0MPa, 1.6MPa, 2.5MPa

Design standard: ISO, DIN/chemical grade, sanitary grade

III Membrane Pilot Machine

Lab scale test Lab scale test Pilot scale test Multifunction equipment

(single ceramic membrane) (double ceramic membrane) (membrane area from 1.5m2-9m2)

APPLICATIONS

1、Fermentation solution clarification technology: animal and plant extracts, enzyme reactions (acrylamide, p-hydroxyphenylglycosine, etc.), organic acids (lysine, L-lactic acid, citric acid, nucleotides, etc.), antibiotics (penicillin, cephalosporin, erythromycin, mucomycin sulfate, erythromycin, vancomycin, etc.) fermentation solution filtration

- Extraction and purification of active ingredients of traditional Chinese medicine

3、Oral liquid clarification and filtration

4、Filtration of soy sauce, vinegar and other brewing products to remove bacteria and impurities

5、Clarification and filtration of fruit juice, beverage and wine

6、De-sterilization and concentration of milk

7、Separation and refinement of fermentation products

8、Oil-containing emulsion wastewater treatment: oil field re-injection water, cold rolling emulsion wastewater, metal cleaning liquid recovery