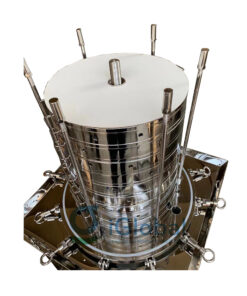

Brief Introduction

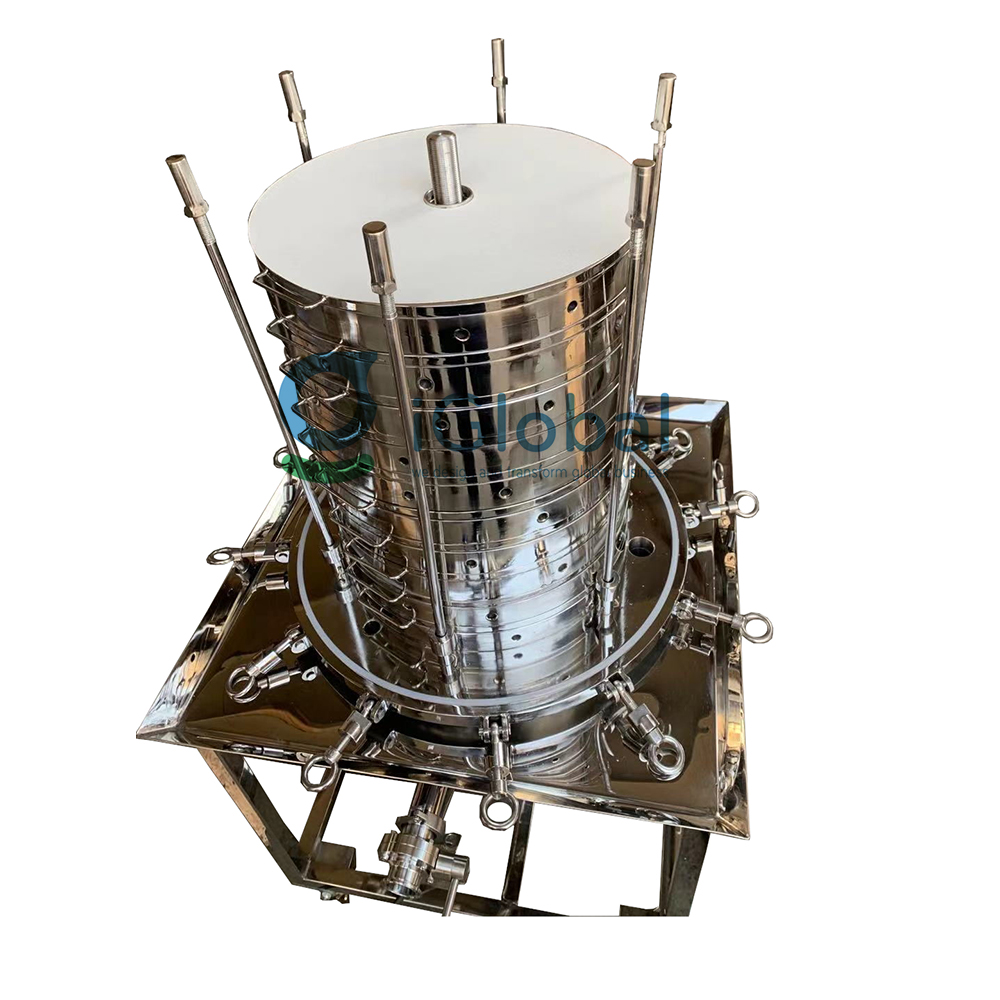

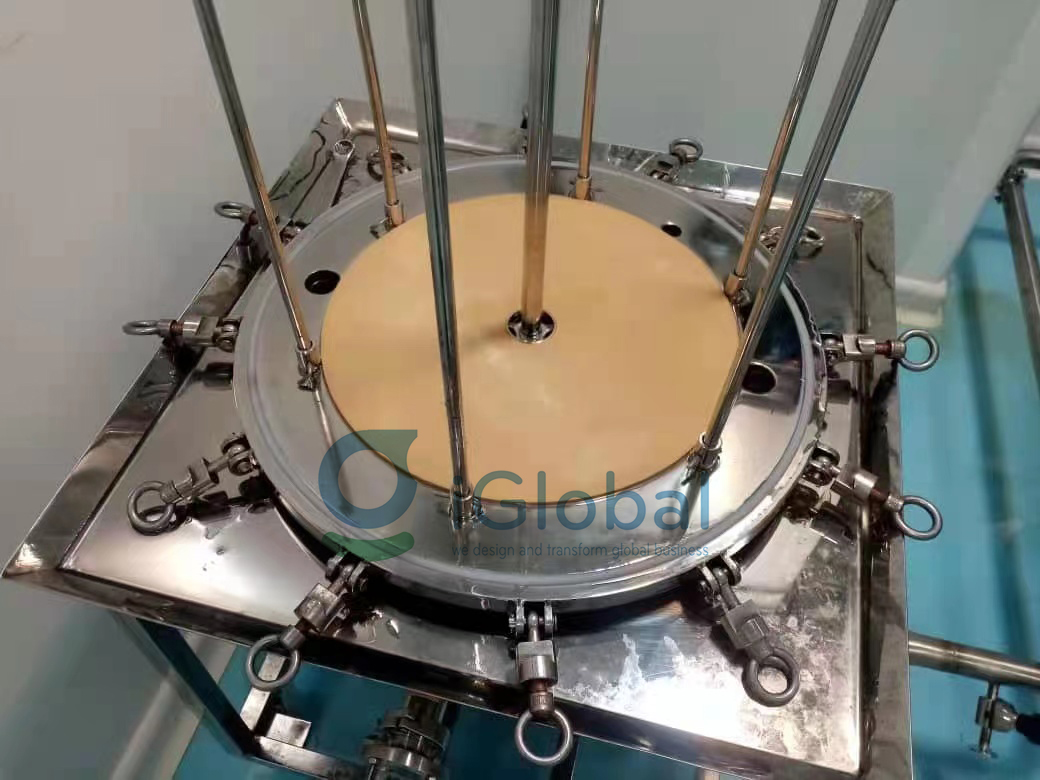

Stainless steel sparkler filter is the most common filter device used in solid-liquid separation, be widely application in pharmaceutical, chemical, beverage, ink, petroleum and other related industries. This equipment can be used for almost any liquid filtration. It can filter to a particle size of 1 micron. Because its design can completely filter the particles, it mainly replaces the re-filtered liquid with low solid content.

At the same time, it is widely used in the pharmaceutical and chemical industries to replace other precision filtration.

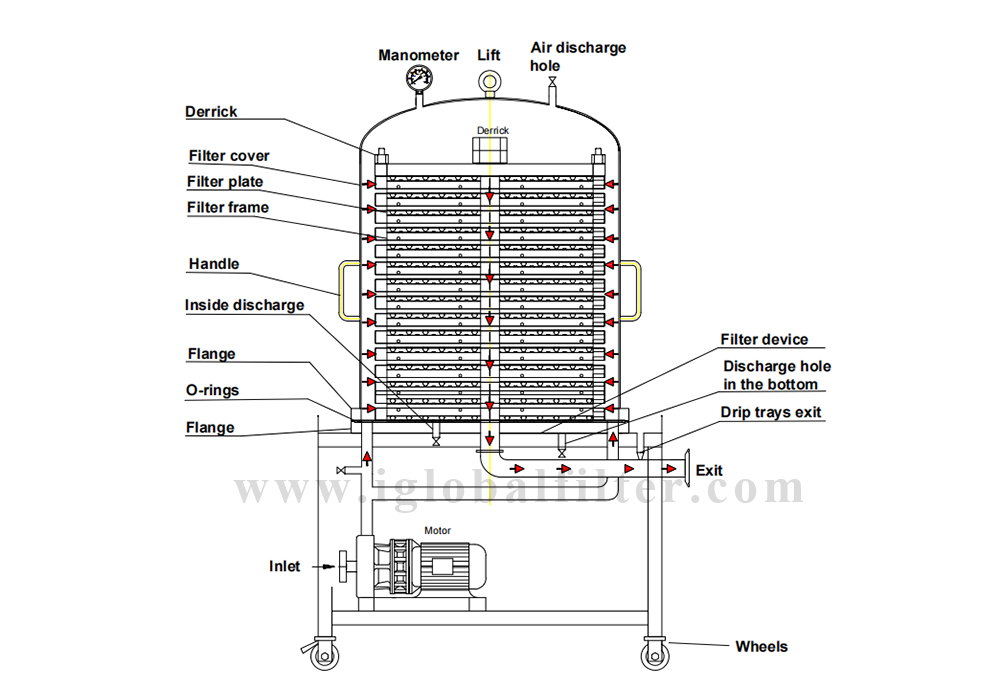

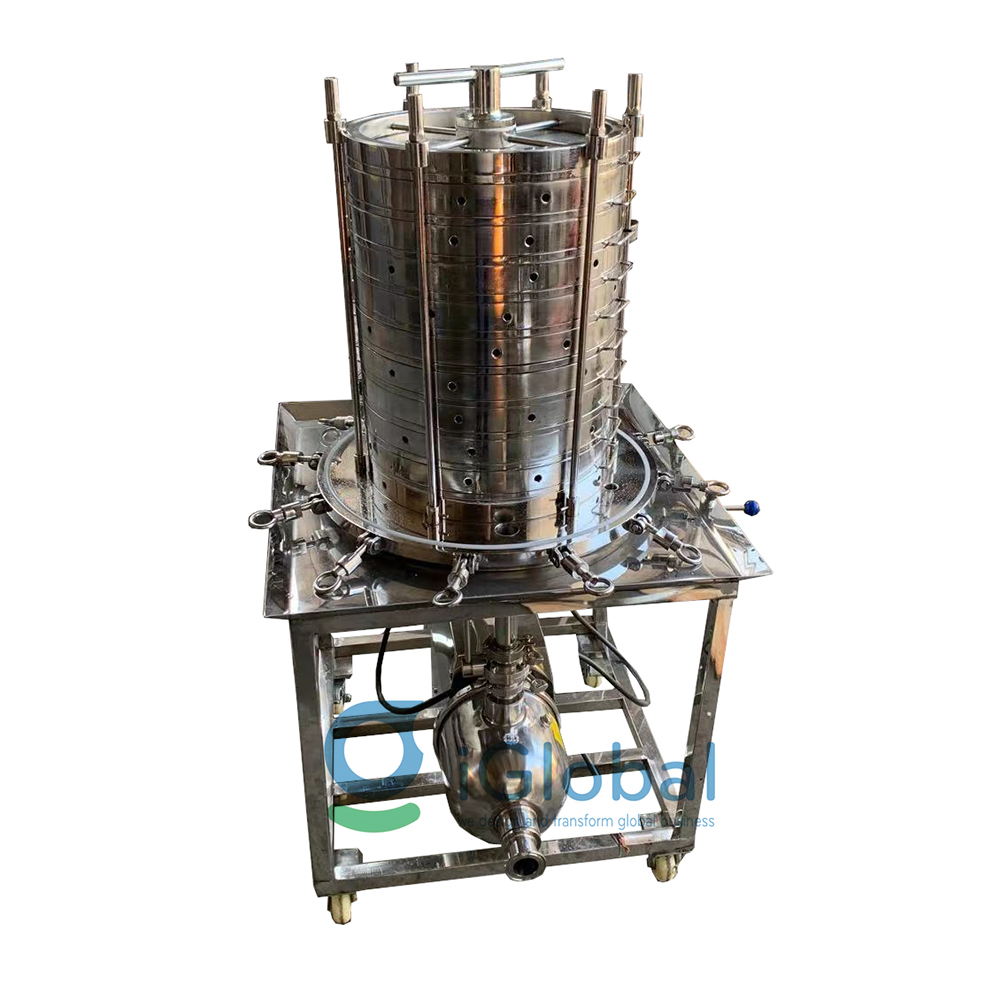

The filter cylinder has an upper cover and a suitable clamping device to obtain an airtight cover. The pressure gauge, the exhaust port and the safety valve are all located on the top.

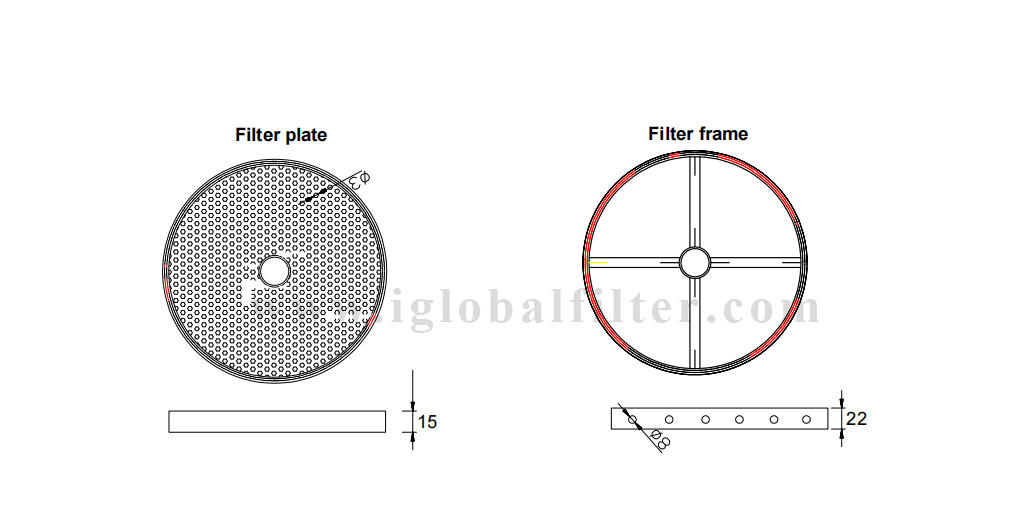

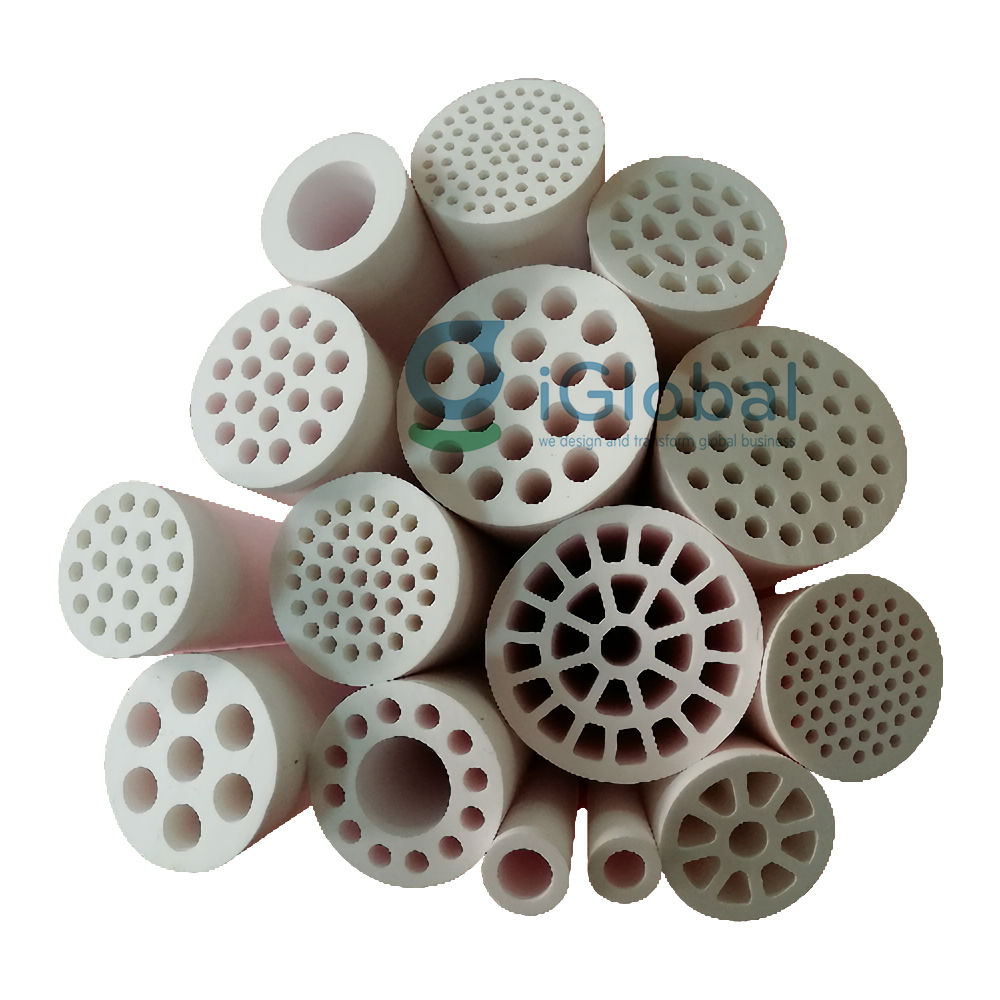

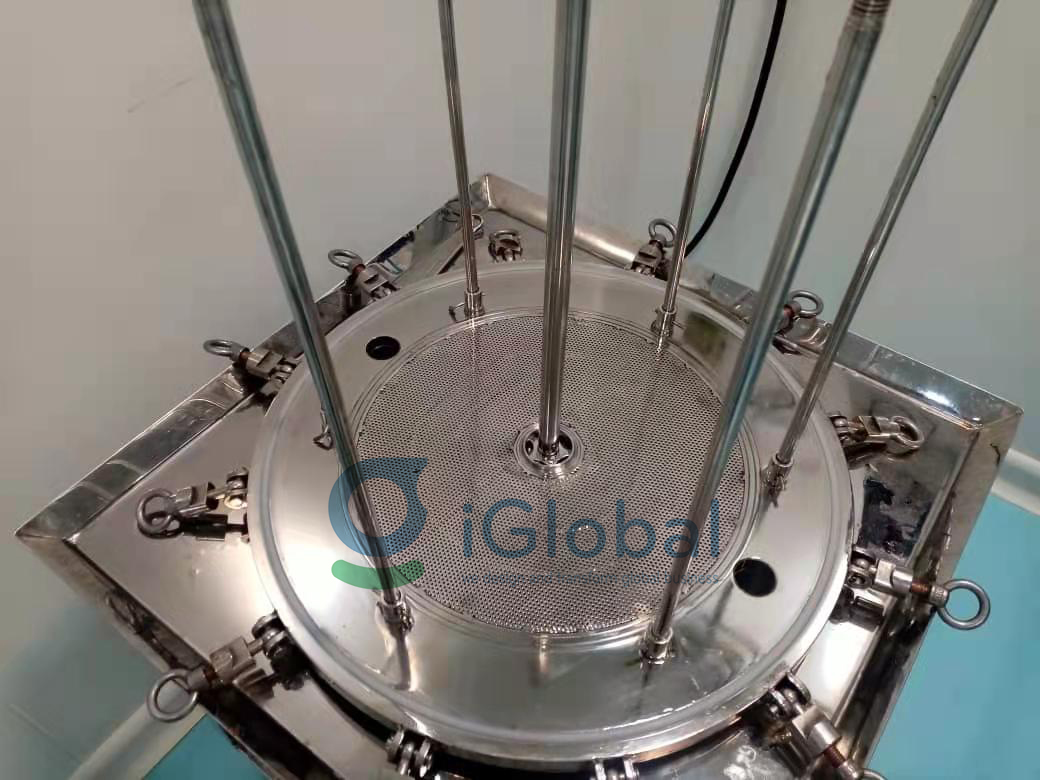

There is an integrated filter assembly inside the cylinder, which constitutes the main filter part of the entire device. The assembly is composed of multiple filter plates, perforated screens, filter media, inner locking cups, bottom assembly plates and top clamping rings.

The whole assembly is connected together with side connecting bolts. With the help of the center bolt, the assembly is fixed to the main fuel tank.

The processing capacity of the sparkler filter depends on the diameter of the filter plate and the number of plates. It will also depend on the filter media provided and the liquid being filtered. According to the particle size of the liquid and solid to be filtered, the filter medium can be selected. The diameter and number of filter plates can be calculated according to the user’s processing requirements.

Mainly Advantage

- Reliable structure, excellent sealing performance, no any leakage

- All material is Stainless steel, can reach medical grade

- While filtering, can keep high temperature if needed

- Easy to operation and maintaining

- Long service life

Install steps:

Technical data:

| Specification | Filter area(m2) | Capacity(L) | Flow(L/H) |

| 8’’ Dia x 6 plates | 0.2 | 4.2 | 450-500 |

| 8’’ Dia x 8 plates | 0.25 | 5.6 | 600-700 |

| 14’’ Dia x 8 plates | 0.65 | 22 | 1300-1500 |

| 14’’ Dia x 10 plates | 0.81 | 27 | 1500-1700 |

| 18’’ Dia x 8 plates | 1.15 | 51 | 2500-3000 |

| 18’’ Dia x 12 plates | 1.72 | 76.5 | 4000-4500 |

| 18’’ Dia x 15 plates | 2.15 | 40 | 5000-5500 |

| 18’’ Dia x 23 plates | 3.3 | 61.5 | 8000-8500 |

| 33’’ Dia x 7 plates | 4.01 | 105 | 9000-9500 |

| 33’’ Dia x 10 plates | 5.51 | 150 | 12500-13000 |

| 33’’ Dia x 14 plates | 7.52 | 210 | 17500-18000 |

The above technical data just for customer reference.

Assemble drawing