Application:

Stainless steel filter press with PP filter plate is widely used in pharmaceutical, chemical, food, beverage, water treatment, brewing, petroleum, printing and dyeing, environmental protection and other industries. It is an ideal equipment for filtration, clarification and purification of various liquids. Especially in the field of biopharmaceuticals;

Characteristic:

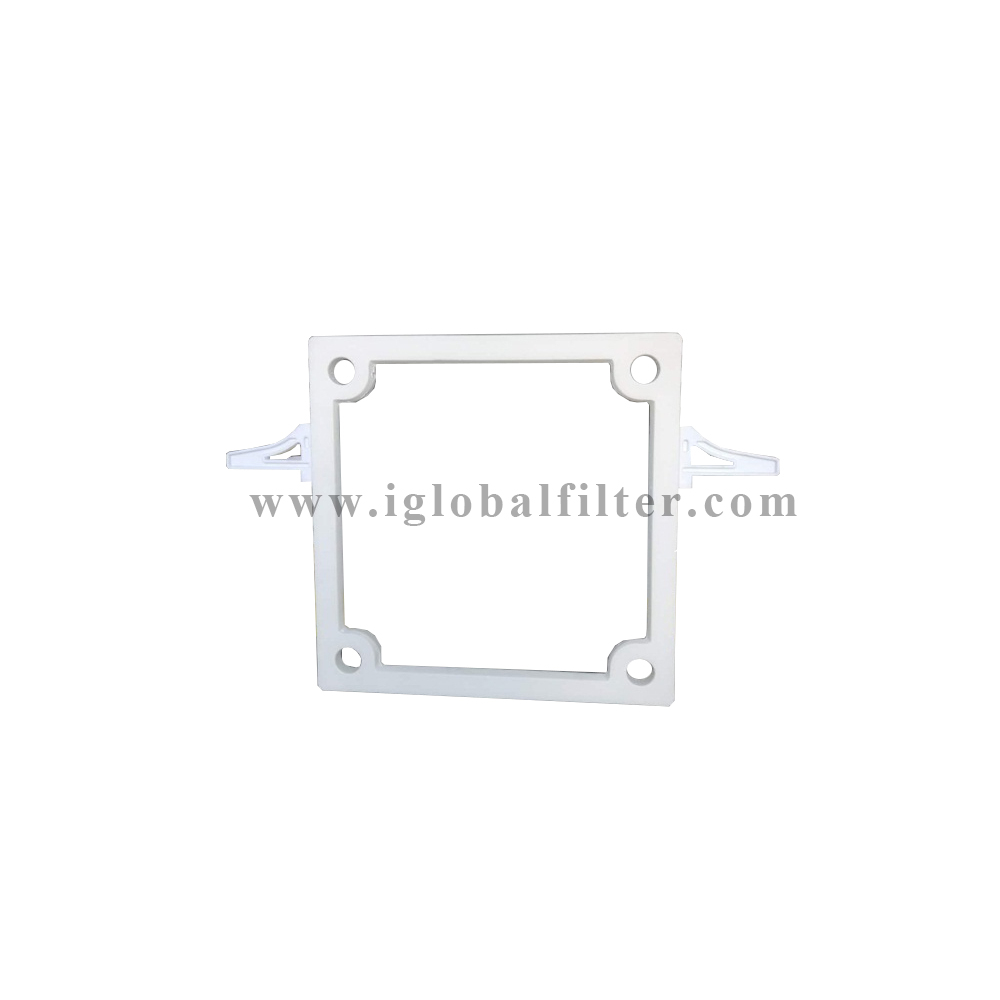

The polypropylene plate and frame filter is composed of a stainless steel frame plus a reinforced polypropylene filter plate and a control system. It has corrosion resistance, good airtightness, fast filtration speed, flexible operation, light weight and low cost;

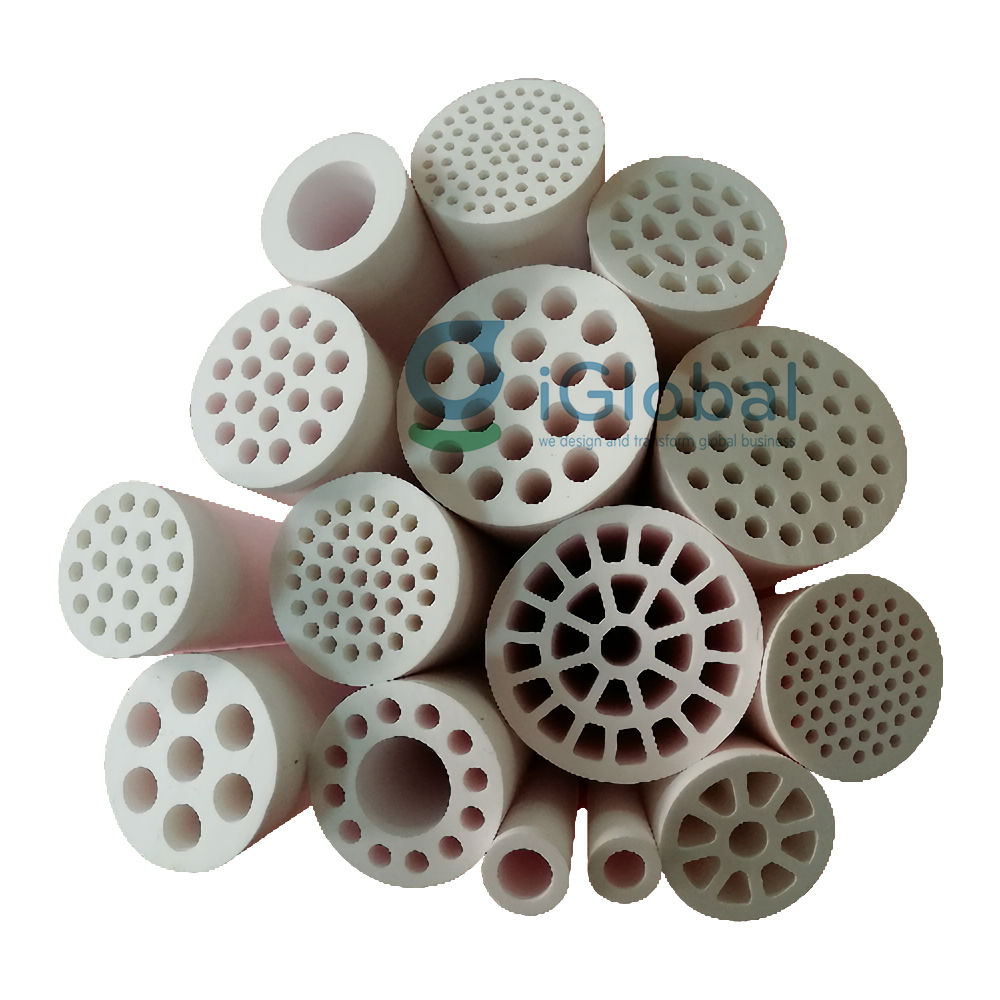

Especially in the case that stainless steel is more expensive, the use of polypropylene can greatly reduce the cost. According to different filter media and production processes (primary filtration, deactivated carbon, particle removal, semi-precision, precision), the microporous filter membrane can achieve the purpose of sterilization treatment, and the number of filter layers can be reduced or increased according to the size of the filter volume. , making it suitable for production needs.

The sealing parts are made of medical silicone rubber or fluorine rubber, which has no leakage and good sealing performance. According to the user’s needs, a special multi-stage filter device can be used to place coarser filter materials and second-stage finer filter materials, which not only saves time and equipment, but also improves filtration accuracy. Plate and frame filter with microporous membrane is the ideal equipment for filtering activated carbon and micron particles.

When this equipment is used in the field of biopharmaceuticals, the matters needing attention are as follows:

- Disinfect the water for injection before use.

- Wet the filter material with distilled water and stick it on the screen, and then press the top plate.

- Fill the pump with liquid before starting, then close the liquid inlet pump, then start, gradually open the liquid valve, and open the exhaust valve to discharge the air in the machine.

- When closing, first close the liquid inlet valve, and then shut down, to prevent the sudden stop of liquid backflow and hit the ring filter material

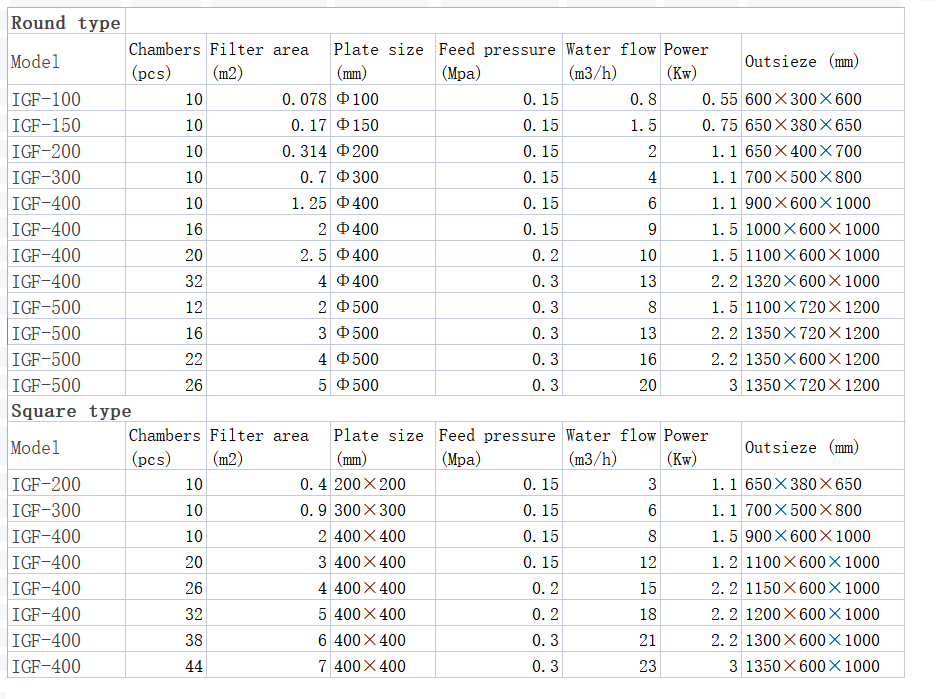

Mainly techncial data

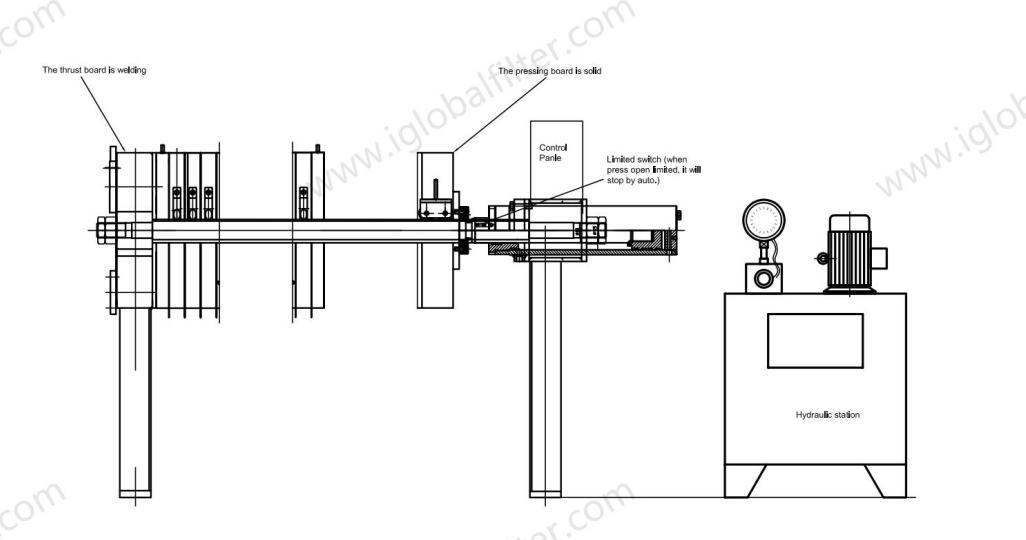

Assemble drawing